ASTM F1249

WATER VAPOR TRANSMISSION RATE (WVTR) MEASUREMENT WITH A MODULATED INFRARED SENSOR

Equivalent to TAPPI T 557, ISO 15016-2, JIS K 7129-2, GB/T 26253, 31355

Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

Where Used

Evaluate materials and finished packages for their barrier characteristics to water vapor. The method is used to optimize a product’s shelf-life or use-life and helps with choosing the most appropriate materials.

Description

Evaluate materials and finished packages for their barrier characteristics to water vapor.

- One side of the sample is exposed to a controlled humidity level (usually 90% RH or 100% RH), while the other side of the sample is swept by a dry nitrogen carrier gas.

- Any transmitting water vapor through the material or package is swept by the nitrogen gas to a pressure modulated infra-red detector, where the water vapor concentration is quantified.

- This water vapor level is reported as a water vapor transmission rate.

- For more details please visit the F1249 page on the ASTM website.

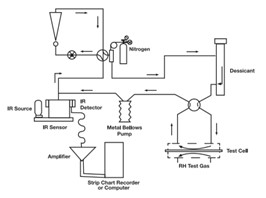

Method Schematic and Related Instrumentation (for both film and package testing)

Note

MOCON® pioneered this test method. With our precise temperature, humidity, flow controls and calibration films, our instruments are the global standard water vapor transmission rate testing. Learn more about about AMETEK MOCON Water Vapor Permeation Analyzers here. For more details on our Lab Testing Services visit our site here.

Results

The transmission rate output is a graph of WVTR vs time (which is key to verifying equilibrium) and data report. Transmission rate test duration can range from a few hours to a few weeks, depending upon the material’s barrier characteristics and test environment.

.jpg?revision=5820dfd6-d31e-4abe-bda8-a948a0c1ae4a&h=278&w=400&la=en&hash=53C0512CEAB55C26F2A0984A0D182FD6)

Download the ASTM F1249 Note