AMETEK MOCON salesman Blake Hasty has spent more than 16 years working in the oil and gas industry, He was an operator for 7.5 years before he got into the commercial side of things, selling gas detection in some capacity for the past decade.

He joined AMETEK MOCON in November 2022 and recently took time to answer a few of our questions about the new pID-Tech eV-NXT sensor.

How does humidity affect PID sensors?

PID sensors hate moisture and typically don’t function well in high humidity. Knowing that high humidity is a crutch for all PID sensors, we went back to the drawing board to determine how we could make the eV-NXT even more robust and resilient to those environmental conditions. AMETEK MOCON has been manufacturing PID sensors for over 20 years and we used our extensive historical data to make the eV-NXT the most reliable and repeatable PID sensor on the market (even in 98% RH environments).

Why was this new sensor necessary? How do we improve upon the last one?

As technology advances in everything from cell phones to computers, electronic components also advance. The eVX sensor itself was developed over seven years ago with the available technology at the time. So, it was an advancement to the next evolution in processing, board components, et cetera to get to today's latest and greatest technology and components. This allowed us to reduce power consumption and improve performance.

What do you think are the biggest selling points? What is particularly unique about this sensor? How does it differ from its predecessor?

One, we simplified the design of its electronic circulatory. This gives us a competitive advantage because it has common components we can source (and second source) from anywhere, which should reduce supply chain constraints.

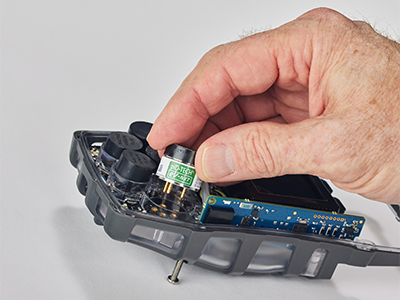

Two, electronically, we went to a factory-adjustable sensor. No matter where you go or what manufacturer you buy from, PIDs are handmade (i.e., the glass is hand-blown). With that, comes irregularities, nuances and differences – there can be up to a 50% difference from one PID sensor to another in the same batch. There’s just variability from sensor to sensor.

With the change in electronic circuitry, we can now dial in the gain at the factory and greatly reduce (if not eliminate) this sensor-to-sensor variability. So, we reduce a potential 40-50% variability sensor to sensor down to 5-10%. This means calibration curves, temperature and humidity compensation curves, and detection linearity are now much more accurate and reliable.

In addition, we have integrated a lamp failure signal into the design to help our customers. This will assist in PM scheduling as well as issue a fault warning to prevent exposure potential when integrated into instruments.

Finally, our sensor is intrinsically safe and designed without the need for additional components. This helps with our customers' integration and streamlines their approval process.

Who is our customer for the eV-NXT? Who benefits most from this new sensor?

A PID sensor detects volatile organic compound (VOC) chemicals. So, most of our customers will be in the oil & gas and chemical industries, where they will be seeking personal protection from exposure to dangerous chemicals such as benzene, toluene, xylene, ethylene oxide, propylene oxide, et cetera.

We can target our low-concentration sensors down into the low parts per billion (PPB) measurements and that will target early warning signs for environmental monitoring. Another application is to implement this into a gas chromatography instrument to see what’s happening inside the pipes. We have some new companies evaluating it now for inline analysis.

What kind of customer response have you received so far?

The response has been good so far. We've only had prototypes in the field, so there hasn't been any adaptation yet. There's particularly been a lot of interest in our new 0-4 parts per million (PPM) sensors, which will take really low PPB measurements.

Historically, that's a tough analysis done by PID to differentiate between the actual signal and the noise (due to the higher gain requirements). We think we've found a much more stable solution than anyone else on the market, so there's a lot of anticipation around that.

Initial testing of the [deployed] sensors has been good. Customers are seeing the results of two decades of data collection and what has become the best PID sensor on the market. Once integrated, the advantages speak for themselves. The baseline stability in extreme environmental conditions, the sensor-to-sensor repeatability, lamp failure signal and more will help evolve what the industry considers the common pitfalls of PID sensors.