Sealing the Edge: WVTR Insights Webinar

Watch as Joel, the longtime lab manager of AMETEK MOCON, gives an in-depth exploration of high-barrier encapsulation and edge diffusion pathways. Learn how key factors – including temperature, humidity and geometry – affect water vapor transmission rates (WVTR) and discover cutting-edge testing methods that redefine material performance limits. Whether you're in research and development (R&D), quality assurance or packaging design, this session will give you valuable insights into optimizing barrier technologies for real-world applications.

.png?revision=1c2ba691-0f2e-4f45-ab1e-585f4ace0799&h=264&w=600&la=en&hash=C1474646C9D713C4D963BF0E1D1C3244)

Which OTR Method is Right for Your Application?

Oxygen Transmission Rate (OTR) is a critical parameter in evaluating the barrier properties of packaging materials and other protective barriers. It measures the amount of oxygen gas that permeates through a material over a given time and area. OTR testing is essential across various industries to ensure product quality, safety and longevity.

- Food Packaging: Testing food packaging for Oxygen Transmission Rate (OTR) is crucial for ensuring product quality, safety and shelf life.

- Healthcare and Pharmaceutical Packaging: Oxygen exposure can degrade active pharmaceutical ingredients (APIs).

- Medical Device Packaging: Maintains sterility and prevents material degradation.

- Industrial Applications: Prevents oxidation and corrosion in metal components.

Choosing Your Ideal OTR ASTM Test:

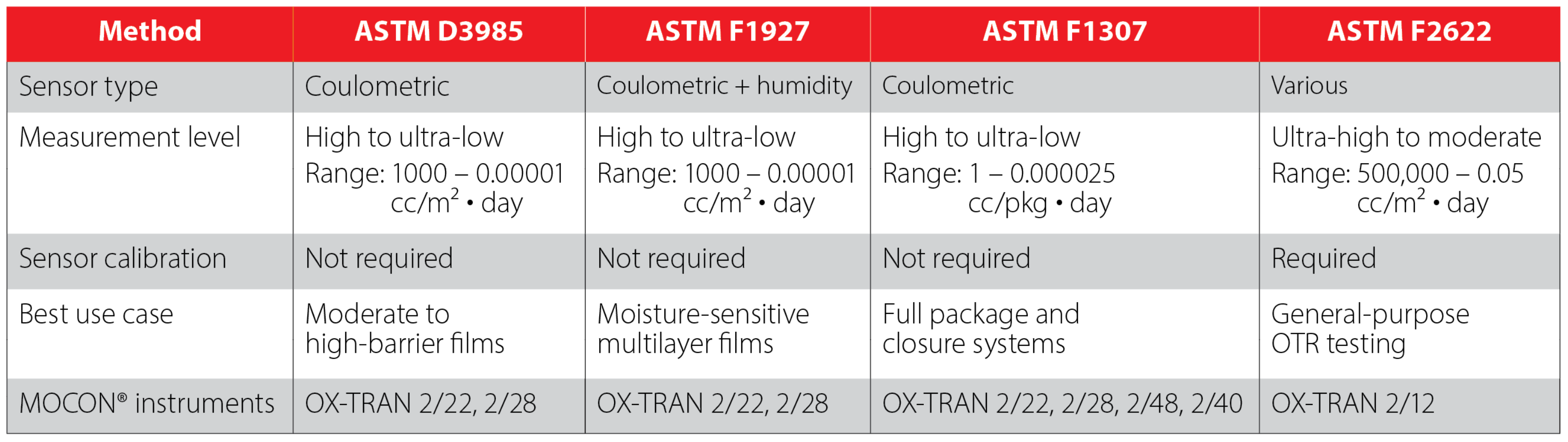

There are four primary ASTM Oxygen Transmission Rate (OTR) test methods -- ASTM D3985, ASTM F2622, ASTM F1927 and ASTM F1307. It is important to understand the technical differences, apparatus details and real-world applications to help guide you in your method selection.

To learn more about the four different methods and how they might apply to your application, click the link to download our new white paper.

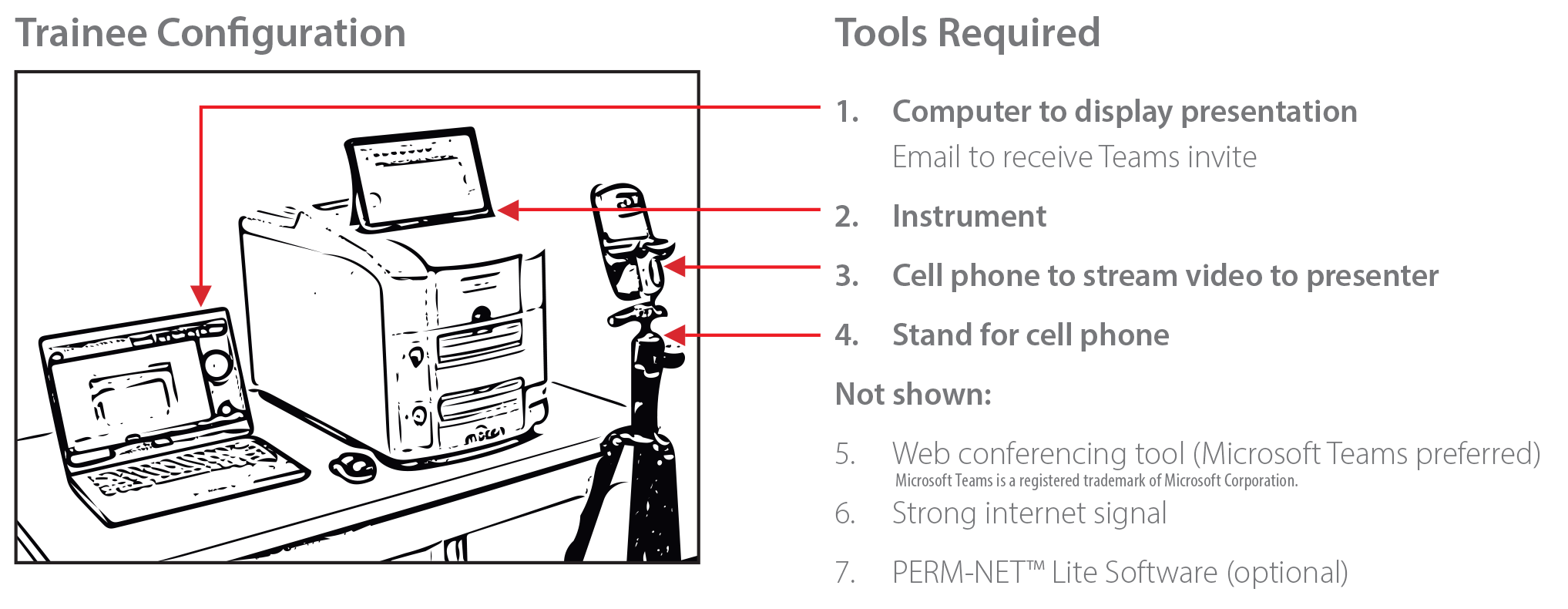

Advanced Permeation Applications Training – Now Available Virtually!

Advanced Permeation Applications Training (APAT) is vital for specialists seeking deeper expertise in barrier testing across industries like pharmaceuticals, packaging and protective equipment. While the standard introductory training covers instrument operation, APAT builds proficiency in permeation fundamentals – diffusion mechanisms, terminology, environmental effects, software capabilities, data analysis, SOP development, troubleshooting and test method selection.

This enhances testing proficiency and trains users to navigate the instrumentation with confidence. Rather than testing for Research and Development (R&D) or Quality Assurance/Quality Control (QA/QC) purposes, available software features on our permeation analyzers can optimize accuracy, repeatability and test throughput.

APAT can be done in person at AMETEK MOCON headquarters or on site at the customer’s lab domestically. Remote training via Microsoft Teams is available for international as well as domestic clients. This course encompasses classroom and hands-on training to familiarize technicians with screen navigation, and a foundational understanding of permeation concepts. By understanding both the science and the tools, technicians reduce the risk of errors, improve reproducibility and support regulatory compliance – ensuring efficient, compliant testing tailored to specific objectives.

Recently published resources: Which ASTM OTR Test Method Is Right for Your Application?

Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Upcoming Events

-

TAPPICon (April 26-29, 2026) in Columbus, OH – speaking/exhibiting

-

Interpack 2026 (May 7-13, 2026) in Dusseldorf, Germany – exhibiting only

Follow us on LinkedIn or visit the events page on our to be the first to know about upcoming industry events and opportunities to learn more about our solutions.