Water vapor transmission rate (WVTR) – how quickly moisture passes through a barrier – matters more than most people realize. Across diverse industries such as food packaging, medical devices, personal protective equipment and high-tech electronics, the right WVTR can dictate product performance, safety and longevity. Measuring WVTR accurately is critical, but which test method works best depends on your material, target barrier level and amount of precision needed.

Why WVTR Testing Matters

In food packaging, poor moisture control can shorten shelf life, impact texture and even lead to spoilage. Minimizing moisture ingress in perishable items such as snack foods or produce is key to preserving crispness and reducing waste. In medical and healthcare applications, breathable but protective materials are vital. Products such as PPE, diapers or wound dressings need to release body humidity without compromising on protection.

And in medical packaging, low WVTR is essential to keep contents sterile and moisture-sensitive drugs stable. Beyond these areas, electronics (like OLEDs or solar modules) often demand ultra-low moisture transmission to protect against performance-degrading humidity.

Choosing the Right WVTR Measurement Method

Not all WVTR testing approaches are created equally. Selecting the right one involves aligning your needs with the measurement method’s strengths. Key considerations include:

- Barrier level: Is your material a very high-transmitter or a nearly impermeable barrier?

- Test sensitivity: Do you need to detect very low levels of water vapor precisely?

- Speed: How quickly do you need results?

- Standards: Are industry standards important to you and if so, what ASTM or ISO method does your application require?

- Sample type: Are you testing flexible films or rigid packages? Or is it a coated paper, a simple polymer or a multilayered structure?

Common WVTR Test Methods

Here’s how the most popular methods compare:

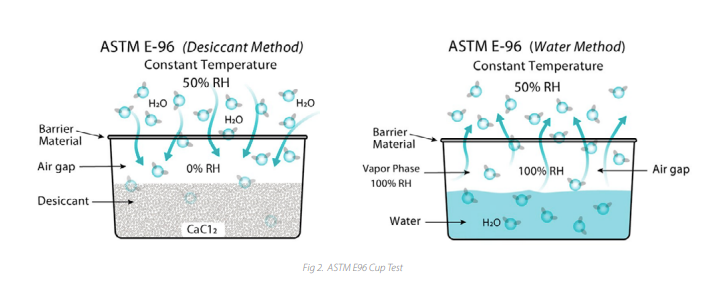

1. Gravimetric (Cup) Method – ASTM E96

- A long-established classic, this method involves placing a desiccant within a sealed cup where the other side is exposed to humidity; any water vapor that passes through is then collected and weighed over time. The slope of the line is used to calculate the transmission rate of the sample.

- Highly versatile. Works well across a broad range of materials.

- Downsides: It’s relatively slow and less sensitive – especially for very low-moisture barriers.

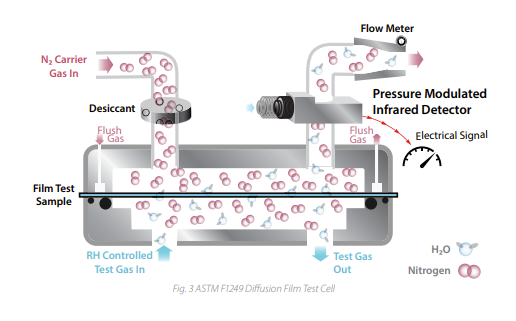

2. Infrared Detection – ASTM F1249

- Uses a diffusion cell: one side is humidified, the other is dry. A nitrogen stream carries transmitting water vapor to a pressure-modulated infrared (IR) sensor for quantification.

- The IR sensor measures how much water vapor absorbs the IR light, compared to a reference, to calculate transmission.

- Faster than gravimetric, and suitable for moderate- to high-barrier films, it boasts excellent repeatability and sensitivity

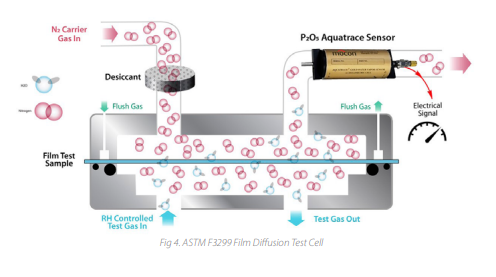

3. Absolute WVTR — ASTM F3299

- Uses an electrolytic (coulometric) P₂O₅ sensor.

- As water vapor is swept into the dry chamber, it gets ionized; the resulting current correlates directly to the quantity of water molecules.

- Extremely sensitive (about 100x more than the IR method!)

- Ideal for ultra-high barrier materials (like those used in electronics).

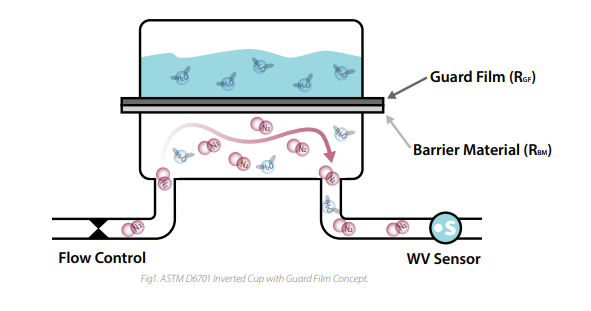

4. High-Transmitter Method – ASTM D6701

- Designed specifically for materials that transmit moisture very quickly (e.g., breathable fabrics, membranes).

- Uses a humidity sensor and a special setup using an inverted cup-like mechanism to maintain constant high relative humidity while measuring.

- Instrumentation (like the MOCON PERMATRAN-W® 101K) is built to deliver very high throughput and accurate and repeatable results for very high transmission rates.

Matching Method to Application

- Flexible, breathable films (e.g., PPE or non-wovens): ASTM D6701 provides fast, accurate measurement even at very high transmission rates.

- Moderate-barrier films (e.g., coated packaging films): ASTM F1249 with IR detection strikes a strong balance between speed and sensitivity.

- Ultra-barrier films (e.g., electronics, OLED encapsulation): ASTM F3299 with an absolute sensor gives unparalleled sensitivity for very low WVTR levels.

- Simpler tests or lower-sensitivity applications: ASTM E96 (cup method) is cost-effective and flexible, though slower and less precise.

Practical Considerations & Expert Support

Labs often prioritize not just the right measurement method, but also repeatability, test duration and alignment with industry standards. That’s why many rely on proven permeation testing tools such as the AQUATRAN and PERMATRAN analyzers from AMETEK MOCON, which are optimized for different methods, from IR to coulometric detection.

Choosing the right test setup may involve tradeoffs. For instance, the absolute (coulometric) method’s sensitivity comes at the cost of longer test cycles, because baseline leak rates must be recalibrated before each run.

On the other hand, IR-based ASTM F1249 tests are faster but may lack the ultra-low detection limits required for cutting-edge high-barrier films.

And while some labs have the in-house capacity to run all these methods, others benefit from external expertise. MOCON, for example, offers not only instruments but also custom app development, lab testing services and training – supporting use cases in food, healthcare, electronics and beyond.

Key Takeaways

1. Match the method to your barrier strength: High-transmitter materials (breathable fabrics) and ultra-barriers (electronics) require quite different approaches.

2. Know your tradeoffs: Speed, sensitivity and repeatability all vary across methods.

3. Leverage experienced partners: For precision, compliance and deeper insights, working with specialist labs can be a gamechanger.

4. Stay aligned with standards: ASTM and ISO methods form the bedrock of credible, repeatable and comparable results across labs and industries.

In today’s high-stakes markets — from food safety to wearable tech — getting WVTR right isn’t a luxury. It’s fundamental. Understanding and applying the right test method ensures your barriers perform as intended, protecting both your product and your reputation.

For a longer exposition on which WVTR testing method might be right for your application, please download the

full white paper.