ASTM D6701

WATER VAPOR TRANSMISSION RATE (WVTR) THROUGH HIGH TRANSMITTING MATERIALS

Equivalent to EDANA/INDA NWSP 070.4.R0 and NWSP 070.5.R1

Standard Test Method for Determining the Water Vapor Transmission Rates Through Nonwoven and Plastic Barriers

Where Used

Evaluate high transmitting materials for their permeability characteristics to water vapor. The method is used to help with characterizing and choosing the most appropriate materials where “breathability” to water vapor is key. Applications include materials within the healthcare, building construction, automotive, filtration and pharmaceutical industries.

Description

This method was developed due to issues with gravimetrically testing (ASTM E96) high WVTR materials. Key problems involved with the historical ASTM E96 method include: an air gap between the water inside the cup and the test film, and the accurately controlling the external film environment (especially right next to the film). With these issues, individual labs might have decent internal repeatability, however comparison with other labs (using other chambers and “air gaps”) would wildly differ, making material comparisons a challenge.

In contrast, ASTM D6701 is a highly accurate and reliable method for measuring WVTR in non-woven materials. Unlike conventional gravimetric methods, such as ASTM E96, D6701 uses a controlled humidity chamber, a very high water vapor transmitting guard film, and an electronic sensor for monitoring the transmitting water vapor.

Comment: This test method analyzes the amount of water vapor (at steady state) that is permeating through a flat film with 100%RH challenging the sample.

Method Summary:

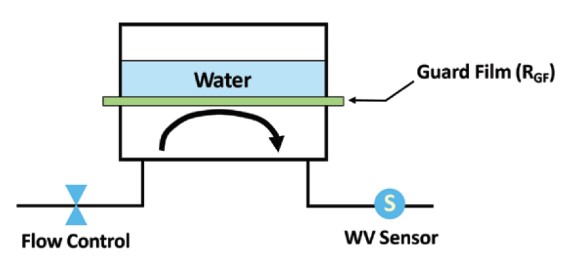

- Apparatus: A diffusion cell is created using a dry chamber (with flowing nitrogen gas), guard film, and a wet chamber. With water against the guard film, this allows for the delivery of extremely high humidity to the Test Sample, while not physically wetting the sample’s surface. The dry nitrogen carrier gas flowing through the chamber is routed to a water vapor sensor.

2. Guard Film Testing: An initial test is conducted to measure the WVTR of the guard film (WVTRGF) and the air gap between it and the evaporator assembly, which generates 100% relative humidity.

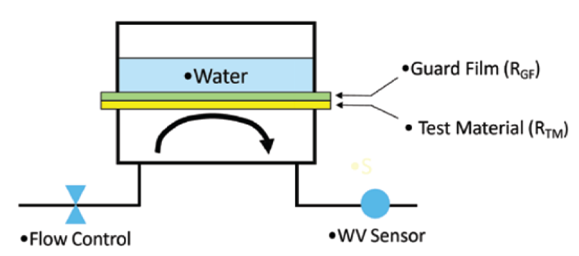

3. Non-Woven Test Material Testing: The film specimen is mounted into the diffusion cell (under the guard film) and the total system WVTRTotal (Guard Film + Test Material) is analyzed.

4. WVTR Calculation: The instrument calculates the transmission rate of the Test Material (WVTRTM) using a resistance equation.

WVTRTM = [ 1/WVTRTotal ‐ 1/WVTRGF ] ‐1

Note

MOCON pioneered this unique test method and is the sole supplier of the instrument. With this methodology, there is finally a repeatable instrument method for characterizing these very high water vapor transmission rate materials. Learn more about Water Vapor Permeation Analyzers by visiting our website.

MOCON pioneered this unique test method and is the sole supplier of the instrument. With this methodology, there is finally a repeatable instrument method for characterizing these very high water vapor transmission rate materials. Learn more about Water Vapor Permeation Analyzers by visiting our website.

Results

Results

The transmission rate output is a graph of WVTR vs time (which is key to verifying equilibrium) and data report. High transmitters analyzed with this instrument test quickly, with a typical throughput of six samples analyzed every 2-4hrs.

Download the ASTM D6701 Note