ASTM E96

WATER VAPOR TRANSMISSION RATE (WVTR) GRAVIMETRIC TEST METHOD

Equivalent to ASTM D1653, TAPPI T 448, T 464, ISO 2528, JIS Z0208, GB/T 1037, DIN 53122-1

Standard Test Methods for Water Vapor Transmission of Materials

Where Used

Evaluate materials for their barrier characteristics to water vapor. The method is used to optimize a product’s shelf-life, or barrier performance, and helps with choosing the most appropriate materials for a specific water vapor barrier application.

Description

This test method gravimetrically determines the amount of water vapor (at steady state) that is permeating through materials such as plastic, paper, fiberboard, or wood products.

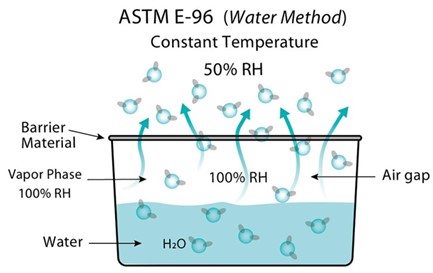

- The material is secured over the volume of the cup. The cup is either filled with desiccant (dry cup) or with water (wet cup). The sample is then placed within a controlled temperature/humidified environment and weighed periodically to determine the material’s weight gain (dry cup) or loss (wet cup) over time.

- A dry cup increases in weight over time as the moisture binds to the desiccant. A wet cup's weight decreases over time as the higher moisture vapor concentration (100% RH) moves through the sample to the chamber’s lower humidity (e.g. 50% RH).

- Knowing the sample area and the rate of weight gain/loss per unit of time allows one to calculate the Water Vapor Transmission Rate.

- For more details and to learn more please visit ASTM E96 on the ASTM website.

Method Schematic (for both dry and wet cup)

Note

In the example above, both cups have the same challenge gradient (50% RH), yet one cup is dry on one side and the other has 100% RH. Such differences may impact the results for highly moisture-sensitive materials, like coated papers, which can swell in the presence of high humidity. Test duration can range from a few days to a month or longer, depending upon the material’s barrier characteristics, test conditions and balance sensitivity. High barrier structures (e.g. foils, metallized and SiOx coated) take a long time to analyze. In general, high barrier materials are best characterized using alternative methods (such as ASTM F1249). Learn more about our Lab Testing Services here.

Results

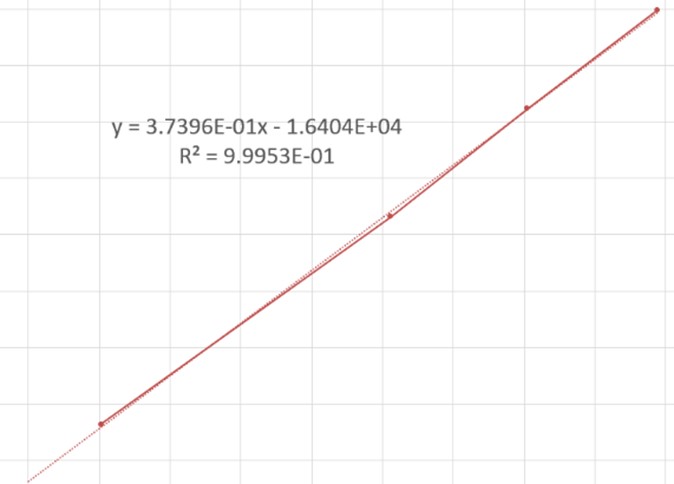

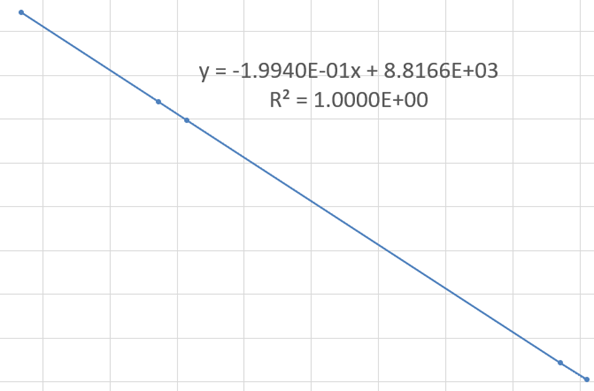

The WVTR of the material are commonly reported units of g/(m2 • day) or g/(100in2 • day) or in an industry niche unit of Perm. The WVTR is determined by the slope of the data.

Download the ASTM E96 Note