HEADSPACE MEASUREMENT OF PERCENT RELATIVE HUMIDITY

Test Method

This document outlines the internal MOCON® test method for measuring headspace percent relative humidity (% RH) using a Vaisala humidity probe.

Where Used

This method is used in typical applications for the measurement of relative humidity within the headspace of moisture sensitive products, such as dry food products, medical devices and some electronics.

Description

This test method utilizes a Vaisala humidity probe to pierce the wall of a package, placing the %RH sensor within the package and measuring the internal humidity level.

- As humidity measurements are relative to temperature, test samples are maintained within our temperature-controlled laboratory (22C +/-2C) for a minimum of 24 hours prior to testing.

- Before sample testing begins, the probe’s performance is verified using humidity standards.

- The sample testing process uses the following steps:

- Attach a septum to the sample package. We utilize the Dansensor® Lippke® 5000 black septum, which adheres to the surface of the package, fits snugly to the probe diameter and prevents room air humidity migration from affecting the reading.With a custom sharp tip affixed to the probe, pierce into the package, leaving the probe tip approximately 1” into the headspace area.

- The sensor will read the humidity within the package. To allow for equilibrium of the probe within the package’s environment, the %RH measurement is taken approximately 5 minutes after insertion.

- Environmental conditions are recorded at the time of testing.

- The final report will contain:

- Sample description

- The humidity measurement (%RH) within each analyzed sample

- The ambient laboratory environment

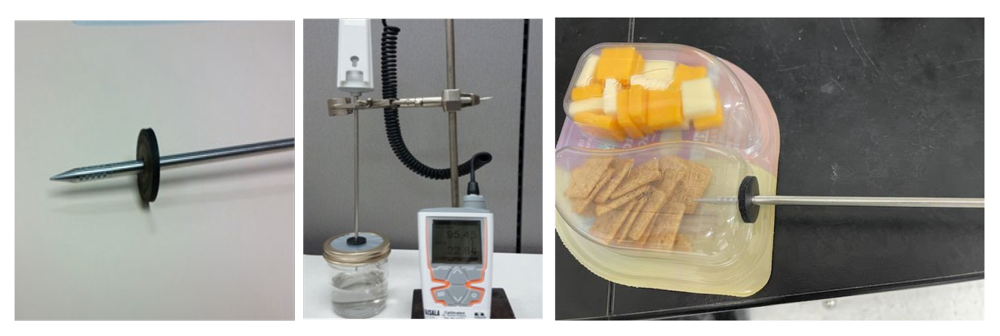

Method Schematic and Related Instrument

Below are photos of the probe, the verification setup and a typical sample.

Notes

- To avoid contamination, the probe needs to be inserted into the headspace of the package. It should not get wet with liquid or pierce directly into a product.

- Within our laboratory’s ambient temperature specification, the repeatability of this probe is +/- 1.5 % RH (0 to 90% RH).

- The probe is ISO 17025 calibrated yearly.

- Learn more about our Lab Testing Services here.

Download the Relative Humidity Note