PACKAGE HEADSPACE TESTING OF OXYGEN (O2) AND

CARBON DIOXIDE (CO2) PERCENTAGES

Test Method

For this method, a headspace analyzer is used to extract a sample of headspace gas from the package and measure the concentrations of O2 and CO2. The analyzer uses an oxygen-specific Zirconia (Zr) or Electrochemical (EC) sensor, and a CO2-specific Infrared (IR) detector.

Where Used

Headspace testing is used to evaluate the performance of Modified Atmosphere Packages (MAP), which can increase the shelf life of foods and medical products.

|

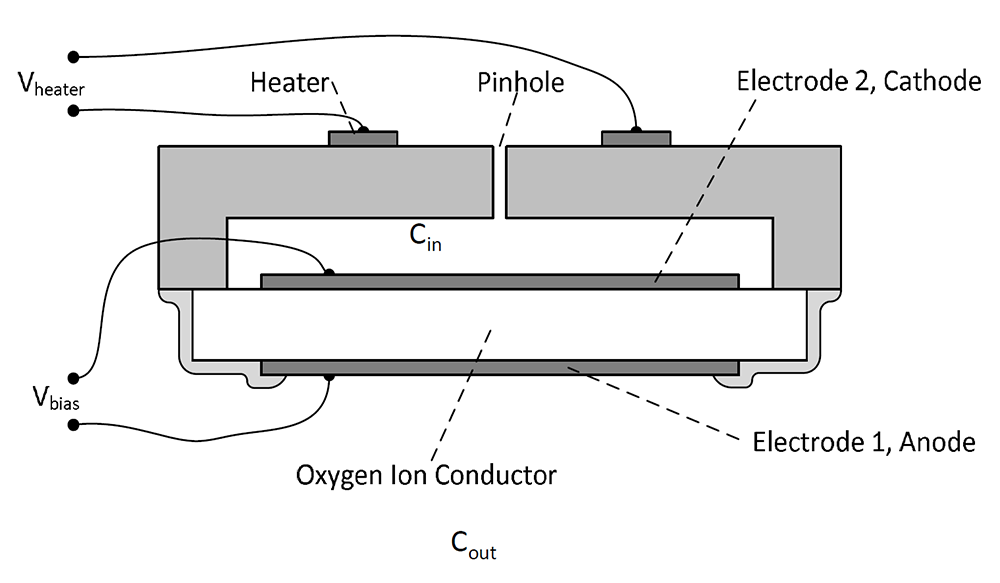

Zirconia Sensor

|

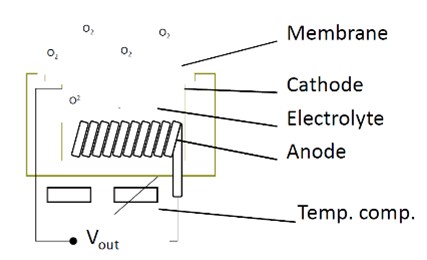

Electrochemical Sensor

|

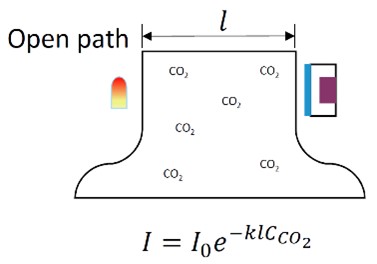

CO2 IR Detector

|

|

|

|

|

Instruments Used

|

Instrument

|

CheckMate® 3 CheckMate® 3

|

CheckPoint® 3 CheckPoint® 3

|

|

Sensor

|

%O2

Zirconia

|

%O2

Eletrochemical

|

%CO2

Infrared

|

%O2

Eletrochemical

|

%O2

Zirconia

|

%CO2

Infrared

|

|

Range

|

0-100%

|

0-100%

|

0-100%

|

0-100%

|

0-55%

|

0-100%

|

|

Accuracy

|

±0.01%

|

±0.1%

|

±0.8%

|

±0.1%

|

±0.1%

|

±2% (0-20%CO2)

±3% (20-100%CO2)

|

Description

The test analyzes the package headspace gas composition to ensure the composition meets specifications.

- Attach a septa to the package. The septa prevents room air from getting into the package while testing.

- Pierce the instrument’s needle through the septa and package surface so that it sits within the headspace.

- Engage the analyzer pump, which pulls the headspace from the package into the instrument.

- Read and record the %O2 and %CO2 composition.

Notes

For greatest %O2 and %CO2 accuracy, utilize the Dansensor® CheckMate 3 with Zr sensor.

Some residual product gases (alcohol, hydrocarbons and CO) can interfere with the Zr sensor. For these samples, an instrument with an EC sensor should be used instead.

With small headspace volumes, the instrument’s sampling (pumping) time needs to be optimized.

Learn more about AMETEK MOCON headspace analyzers here and our Lab Testing Services here.

Common Accessory (for rigid packages)

The Dansensor Can Piercer for gas detection is used for accurate headspace sampling of cans, containers and bottles. This product is an ideal can piercer for the beverage industry.

The Dansensor Can Piercer for gas detection is used for accurate headspace sampling of cans, containers and bottles. This product is an ideal can piercer for the beverage industry.

Milk Powder cans

Wine bottles

Soft drink cans

Ready to drink containers

PET Bottles

Download the Note on Headspace %02