DETERMINING FILM SAMPLE THICKNESS

Test Method

This test method is used to measure a film sample's thickness.

Where Used

The sample is typically a flat film, or a flat piece of material sectioned from a tray or pouch side wall. MOCON does not have a method for measuring the thickness of a curved (bottle wall) or very bumpy sample. Note: this method is most commonly requested when analyzing small batch or lab-created samples comprised of simple structures.

Description

The test method analyzes the sample thickness. As the act of measuring touches the sample’s surface, it will be tested to measure material thickness after transmission rate testing. This minimizes the chance of scratching or damaging the sample prior to gas barrier transmission rate testing. However, when samples have applied coatings to paper, they will be tested prior to transmission rate testing as the material could swell with high humidity exposure.

- Prior to each test, a standard reference gauge material is measured and recorded for instrument verification.

- The flat surface of the film is identified and the thickness is measured.

- For each sample, five points are analyzed (the center and four points around the perimeter) and recorded.

- The average thickness is determined and reported.

- Learn more about our Lab Testing Services here.

Instruments Used

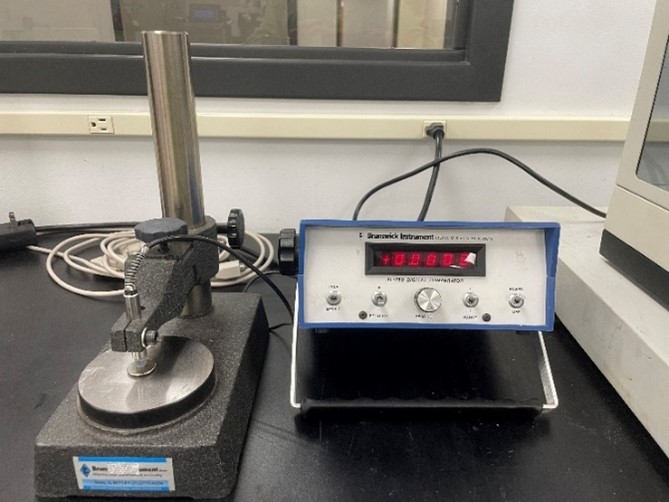

|

Instrument

|

Brunswick Instrument XL-750 Digital Comparator

|

Mitutoyo 547-500S

|

|

Range

|

0 - 0.03inch (0 - 0.76mm)

|

0- 0.47 Inch (0-12mm)

|

|

Accuracy

|

+/- 0.0001” (+/-2μm)

|

+/- 0.001” (+/-20μm)

|

Note: Both instruments are ISO 17025-calibrated yearly.

Download the Note on Film Thickness Measurement