ASTM F3136

OXYGEN TRANSMISSION RATE (OTR) TESTING WITH A FLUORESCENCE DETECTION METHOD

Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting using a Dynamic Accumulation Method

Where Used

The Oxygen Transmission Rate is an important determinant of packaging functionality afforded by packaging materials for a wide variety of products including food, pharmaceuticals and medical devices where breathability can be a concern. Samples such as: coated papers, perforated films, and rigid package with known leaky closures are often analyzed with this method. For barrier applications, other OTR test methods (ASTM D3985 and F1307) are more appropriate.

Description

This test method measures oxygen concentration via a fluorescence methodology. The steps of the test include:

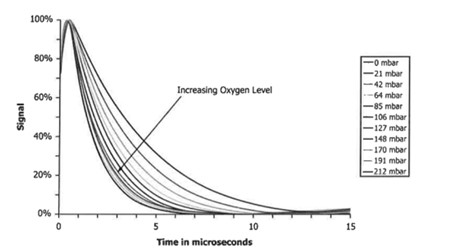

- Shine a specific wavelength onto the fluorescence material and record the sensor’s response time.

Note: The response of the sensor is impacted by the concentration of oxygen in the sensor’s environment.

- By measuring the decay rate of the fluorescence response, the percent of O2 is determined.

- When set up with a permeation test:

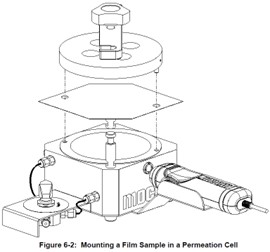

- The fluorescence sensor is placed into a diffusion cell, and the cell is purged with N2 gas to remove the ambient oxygen.

- The N2 flow is turned off, allowing oxygen transmitting through the sample to accumulate in the cell.

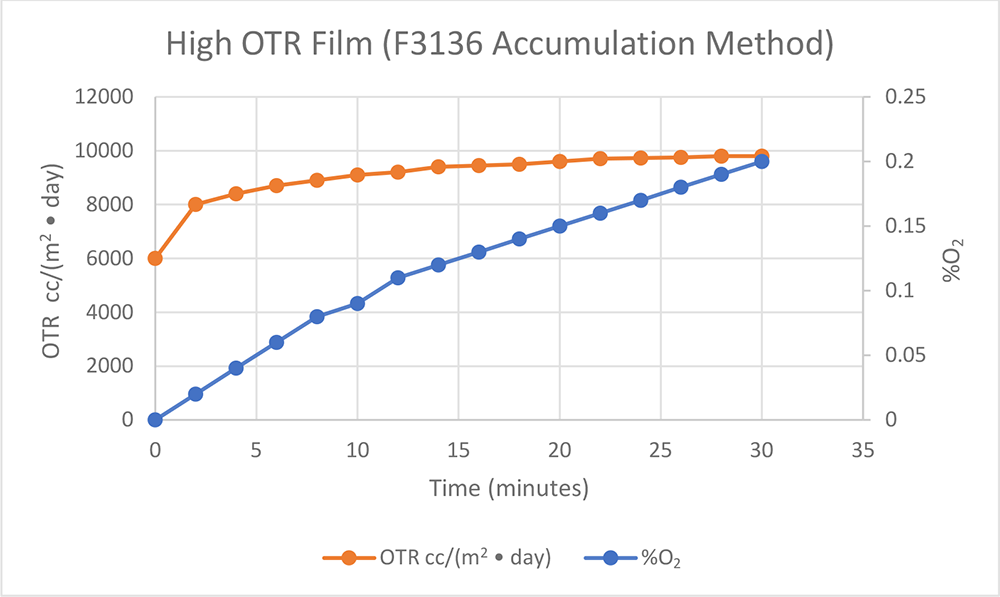

- Using the slope of the accumulating %O2 vs. time, the OTR through the film is accumulated. This calculation is analogous to ASTM E96 gravimetric accumulation method.

- Common units for OTR are cc/(m2 • day) or cc/(100in2 • day).

- For more details on ASTM F3136 please visit the ASTM website.

- Learn more about our Lab Testing Services here.

Fluorescence Response Graph, and Related Test Apparatus

Note

As this test method does not use a flowing carrier gas stream for the oxygen analysis, it is the only method that can be utilized for porous, perforated or leaky samples.

Below is an example of an ASTM F3136 transmission rate graph.

Download the ASTM F3136 Note