ASTM F2476

CARBON DIOXIDE TRANSMISSION RATE (CO2TR) TEST METHOD

Equivalent to ISO 15105-2 and DIN 53380-4

Standard Test Method for the Determination of Carbon Dioxide Gas Transmission Rate (CO2TR) Through Barrier Materials Using an Infrared Detector

Where Used

Evaluate materials and finished packages for their barrier characteristics to carbon dioxide. The method is used to optimize a product’s shelf-life or use-life and helps with choosing and developing the most appropriate materials.

Description

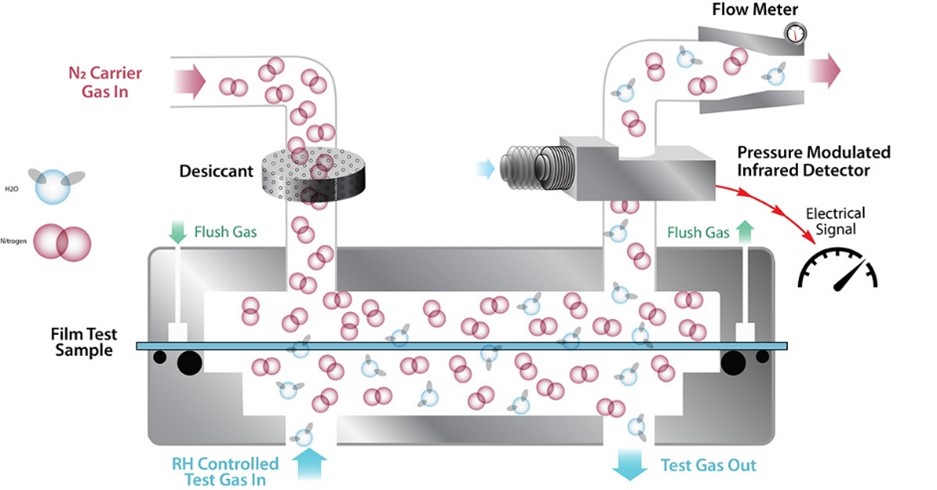

This test method analyzes the amount of carbon dioxide that is permeating through a flat film (such as the sidewall of a pouch) or package (such as a full pouch, tubing or a carbonated soft drink bottle).

- One side of the sample is exposed to a known carbon dioxide gas concentration (usually 100% CO2), while the other side of the sample is swept by a dry nitrogen carrier gas.

- Any transmitting carbon dioxide through the material or package is swept by the nitrogen gas to a pressure modulated infra-red detector, where the carbon dioxide concentration is quantified.

- This carbon dioxide level is reported as a carbon dioxide transmission rate.

- For more details about ASTM F2476, please visit the ASTM website.

Method Schematic and Instrumentation

Note

MOCON® pioneered this test method. With our precise temperature, flow control and calibration films, our instruments are the global standard for carbon dioxide transmission rate testing. For information about CO2TR Permeation Analyzers, please visit our website. Learn more about our Lab Testing Services here.

Results

The transmission rate output is a graph of CO2TR vs time (which is key to verifying equilibrium) and data report. Transmission rate test duration can range from a few hours to a few weeks, depending upon the material’s barrier characteristics and test environment.

Download the ASTM F2476 Note