ASTM F2095

LEAK TEST VIA PRESSURE DECAY

Standard Test Methods for Pressure Decay Leak Test for Flexible Packages With and Without Restraining Plates

Background

A leak test checks a package for leaks, whether through material defects (holes) or channels in seals. During this test, the package is inflated to a predetermined pressure (typically 10-30% of the packages burst pressure), the pressure regulation stops, valves close, and the internal pressure of the package is monitored. A loss in pressure indicates a leak in the package.

Where Used

This method is used in Quality Control to verify package integrity. It works well with the headspace gas challenge of the package. The method does not work well with liquid against a seam as the liquid can “clog” a leak path.

Description

- A septum is applied to the package.

- The needle pierces into the headspace of the package through the applied septum.

- The package is inflated to the test pressure.

- The test pressure is maintained and stabilized in the Settling time (this allows for some level of innate material stretching of the inflated sample).

- At the start of the test the pressure regulation stops and valves are closed, while the pressure continues to be monitored. The pressure drop is measured during this time.

- For more details about ASTM F2095, please visit the ASTM website.

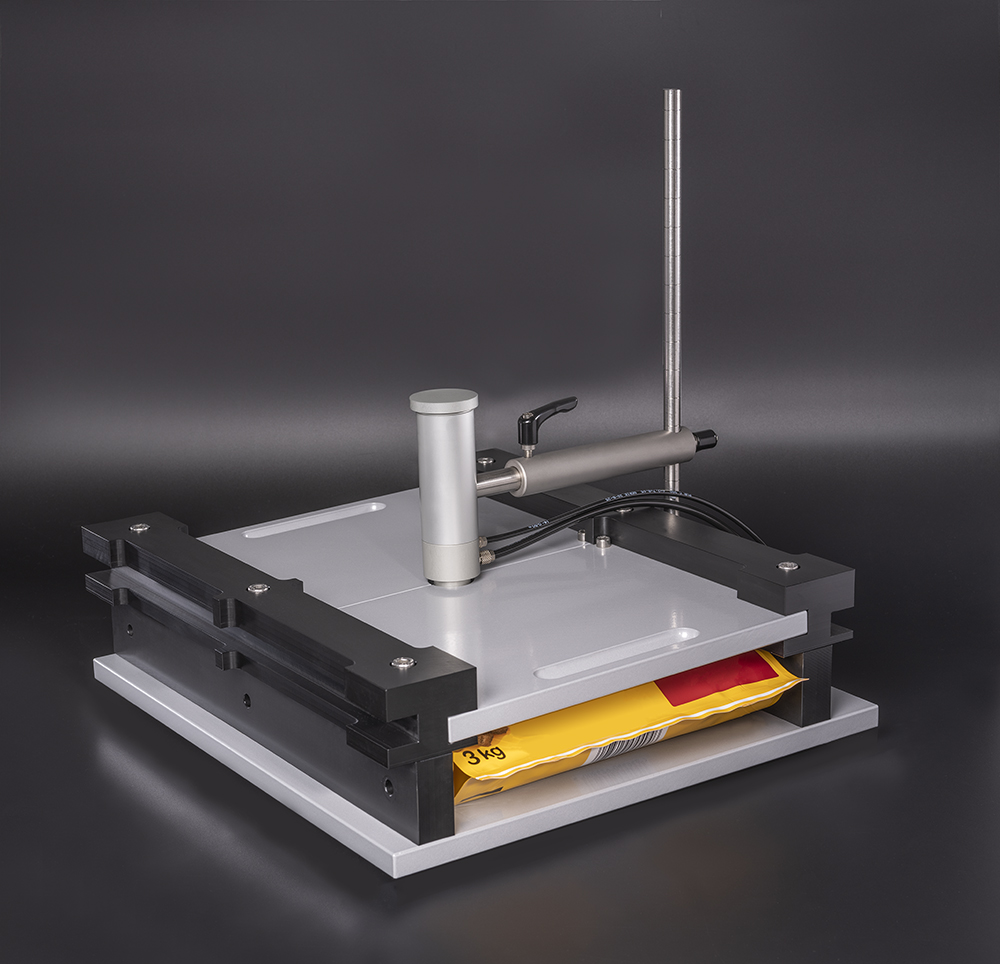

Related Instrument

With the Dansensor® Lippke® 5000, samples can be tested either unrestrained (open on all sides) or restrained. The restraining plate helps to improve repeatability when testing lidded trays and larger pouches, which can “peel” at their seams if not restrained.

Notes

- The Dansensor® Lippke® 5000 incorporates both a High and a Low level pressure sensor to optimize for the pressure needs of a specific package.

- Every package configuration requires an optimized test method with known “good” and “bad” leak controls.

- The pressure decay test method has been demonstrated down to levels of 12.7µm leak size.

- A Leak Simulation Kit is available that can be used as a QC control for creating a known hole size or verifying instrument performance.

- Learn more about our Dansensor Lippke 5000 here and our Lab Testing Services here.

Results

Typical results from a leak test are shown in the graph below:

Pass = the pressure drops less than allowed in the pre-set limits

Fail = the pressure drops more than the allowed pre-set limits or if the package bursts during inflation instrument performance.

Download the ASTM F2095 Note