ASTM F2054/F1140

RESTRAINED/UNRESTRAINED BURST TEST

Standard Test Methods for Burst Testing of Flexible Packages Seals

Using Internal Air Pressurization, With or Without Restraining Plates

Where Used

Evaluate packages to determine the weakest area of a package system. It is often used as a QC test to quickly confirm overall package strength meets internal specifications.

Description

- A septum is applied to the package.

- The needle pierces the package through the applied septum into the headspace of the package.

- The package is inflated to the set pre-fill pressure.

- The pressure in the package is increased at the pre-set rate until the package bursts or until the maximum specified pressure is reached.

- For more details on ASTM F2054 or ASTM F1140, please visit the ASTM website.

Related Instrument

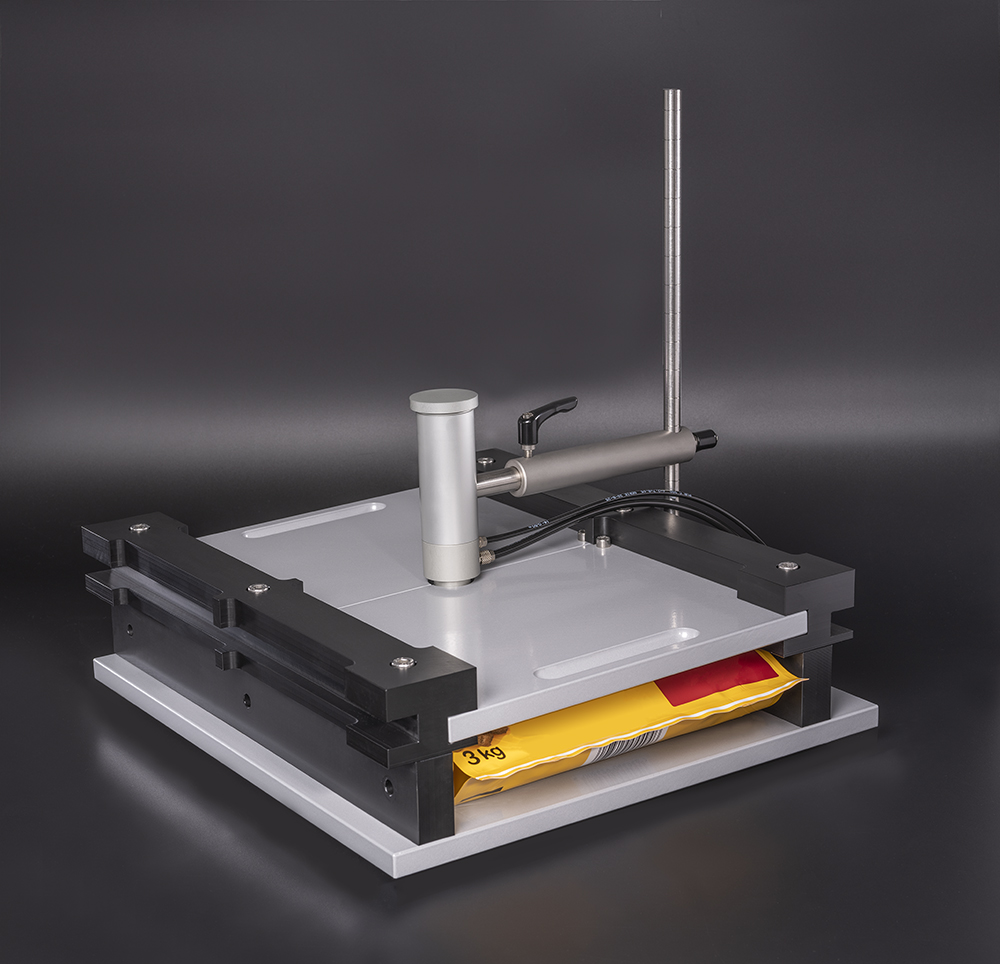

Samples can be tested either unrestrained (open on all sides) or restrained. The restraining plate helps to improve repeatability when testing lidded trays and larger pouches, which can “peel” at their seams if not restrained

Notes

- The Dansensor® Lippke® 5000 incorporates both a high and a low level pressure sensor to optimize a test method to the burst pressure needs of a specific package.

- The compressed air supply must be dry, clean, and free from oil.

- An optional pressure regulator/filter unit is available which ensures the air quality fulfills the requirements.

- The Lippke 5000 has a PC Software option for storing quantitative as well as pass/fail results. The software has a graphing feature that makes it easier to troubleshoot and “see” what your package is doing.

- Learn more about our Dansensor Lippke 5000 here and Lab Testing Services here.

Results

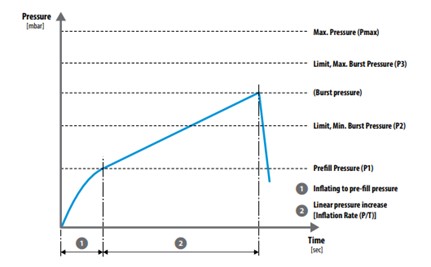

Typical results from a burst test are shown in the graph below:

Pass = the package burst pressure is within the established burst limits.

Fail = the package burst pressure is outside the established burst limits or has a gross hole/defect

that inhibits pressurization.

Download the Note on Burst Testing