ASTM F1307

OXYGEN TRANSMISSION RATE (OTR) OF PACKAGES

Equivalent to ISO 15105-2, JIS K 7126-2, GB/T 31354, DIN 53380-3

Standard Test Method for Oxygen Gas Transmission Rate Through Dry Packages Using A Coulometric Sensor

Where Used

Evaluate whole finished packages for O2 gas barrier characteristics. The method is used to optimize a product’s shelf-life directly correlated to the finished package’s barrier performance. It’s used for analyzing components (such as a tray) or “whole packages” (such as a tray with lidding attached). This measurement is very useful for evaluating both materials and processes.

Description

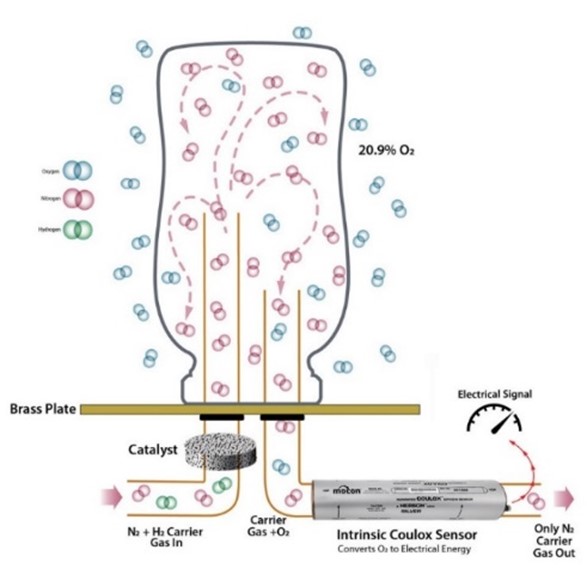

This test method analyzes the amount of oxygen gas that is permeating into a whole packaging system

(i.e. pouch/container side walls and/or closure/lidding).

- The outer surface area of the package is challenged with oxygen gas (20.9% in most cases), while the inner volume of the sample is swept by a dry nitrogen carrier gas.

- Any transmitting oxygen through the sample is swept by the nitrogen gas to a coulometric detector, where the transmitting oxygen is measured.

- The common unit for OTR of a package is cc/(package • day).

- For more details on ASTM F1307 please visit the ASTM website.

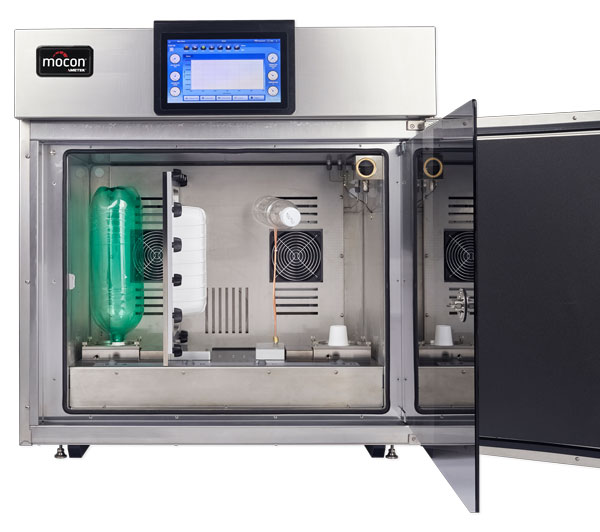

Method Schematic and Related Instrument

Note

MOCON® pioneered this test method and our patented Coulox® sensor is the most sensitive oxygen sensor for permeation testing. With our precise temperature, humidity, flow controls and calibration films, our instruments are the global standard for this test method. Learn more about AMETEK MOCON OTR Permeation Analyers here. And learn more about our Lab Testing Services here.

Results

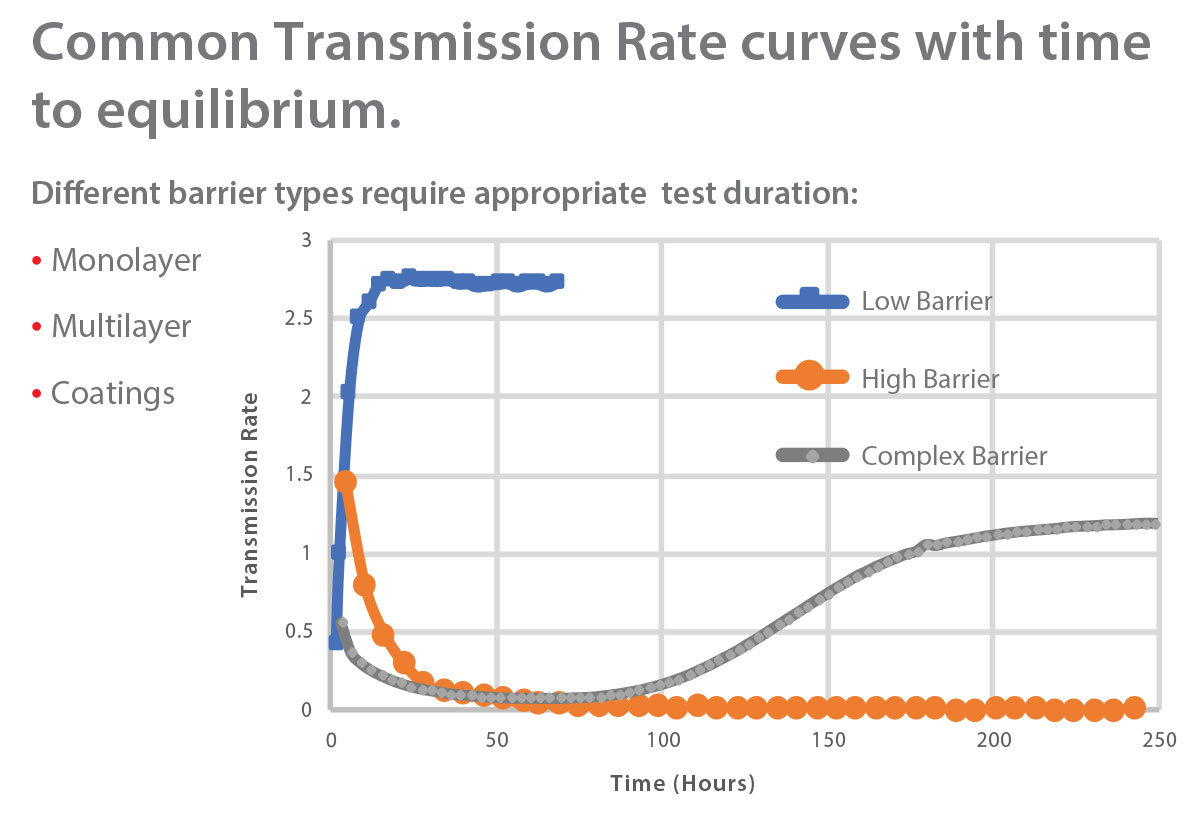

The transmission rate output is a graph of OTR vs time (which is key to verifying equilibrium) and data report. Transmission rate test duration can range from a few hours to a few weeks, depending upon the material’s barrier characteristics. High temperatures lead to higher transmission rates and faster tests, while low temperatures yield lower transmission rate values and longer test durations. Additionally, moisture sensitive samples (e.g., EVOH, Polyimides and Coated Paper) have OTR’s that are impacted by humidity. Knowing your product’s needs and storage conditions is important for optimizing the appropriate test environment.

Download the ASTM F1307 Note