PermWare® update for Windows® 11

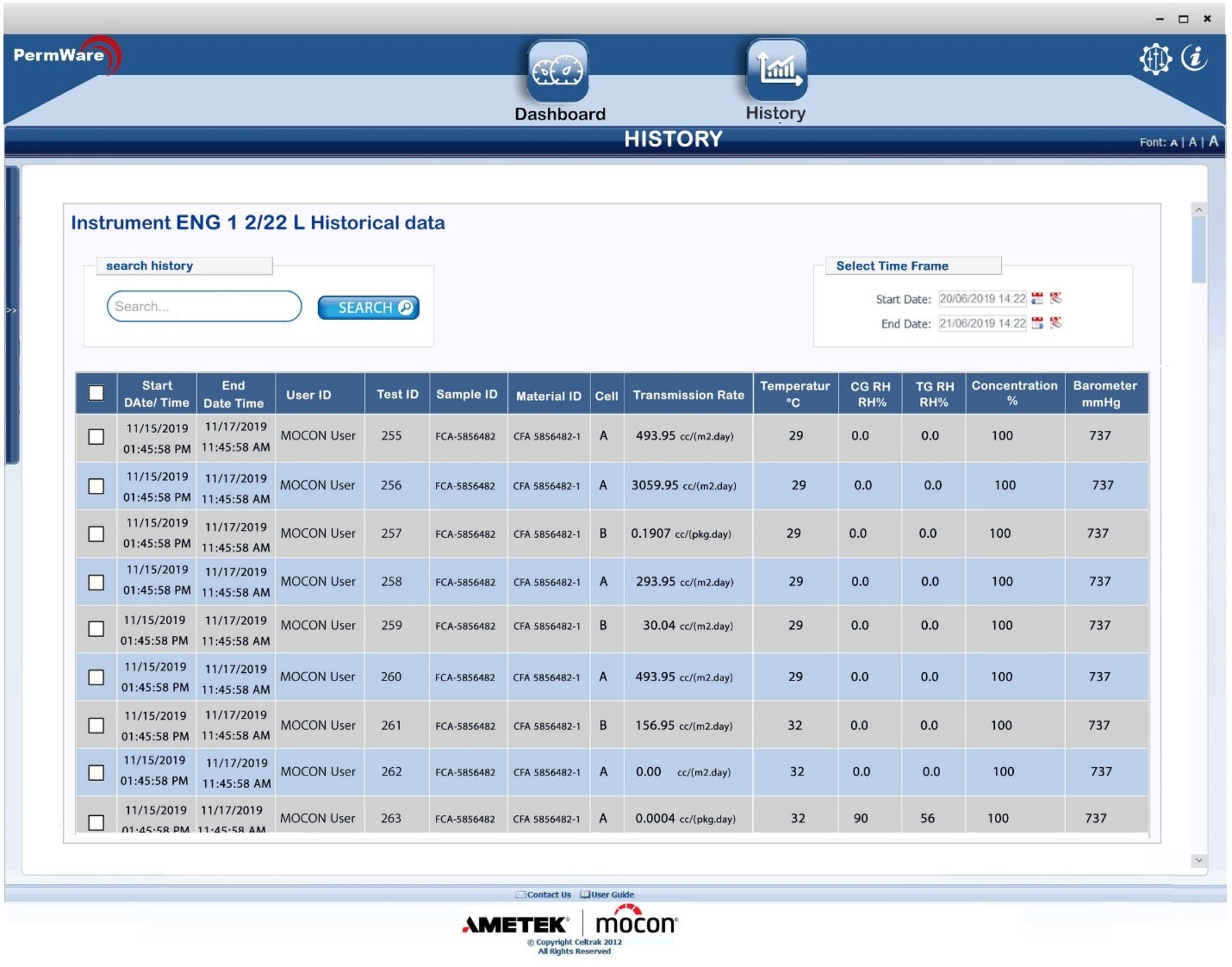

Many AMETEK MOCON customers rely on our advanced data collection and permeation laboratory management system, PermWare. This powerful tool seamlessly connects all MOCON permeation instruments in your lab, consolidates test reports into a single database, and provides an intuitive dashboard for monitoring next-generation instruments. Originally designed for Windows® 10, PermWare has been updated for compatibility with Windows 11 PCs.

Windows® is a registered trademark of the Microsoft Corporation

Our PermWare software is especially beneficial for laboratories operating multiple MOCON permeation instruments. Its centralized test report database features powerful sorting, filtering and formatting tools, enabling scientists to efficiently extract and analyze desired test reports. The dashboard provides real-time, cell-by-cell status updates for all connected instruments, using simple color indicators and digital displays for critical parameters. Additionally, it offers remote access to each next-generation instrument screen from a central PC.

For more information about PermWare, download our latest brochure.

Download Brochure

Custom Package Testing Cartridges

Permeation testing has evolved from simple film testing using gravimetric (water vapor cup tests) and manometric gas transmission rate film tests to more accurate, efficient and automated instrumental methods.

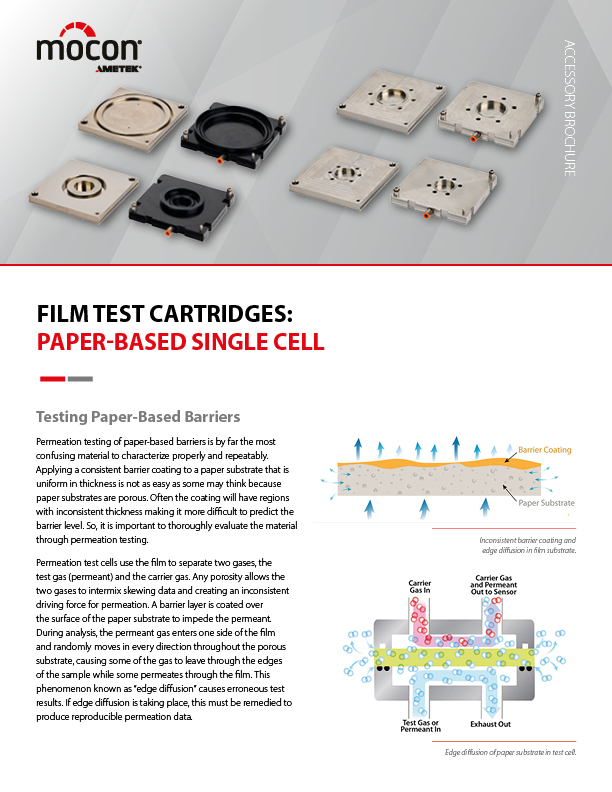

Innovative film-testing cartridges developed by MOCON streamline sample preparation and enhance versatility, while significantly improving data accuracy and reproducibility. These advantages become even more impactful when testing packages, where precision and consistency are critical.

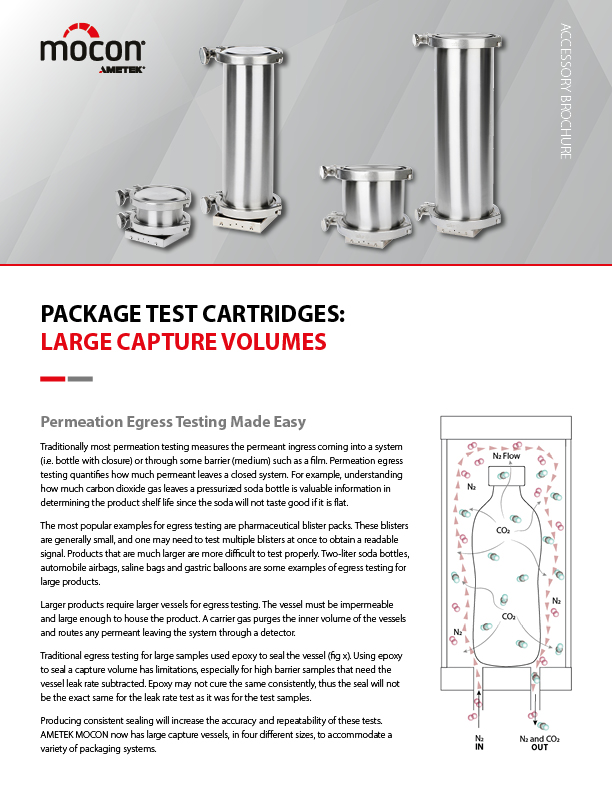

Historically, package preparation for permeation testing has often been cumbersome and subjective. However, the next-generation MOCON Package Test Cartridges have significantly simplified the process for novice technicians and those laboratories repeatedly testing the same QC samples.

By eliminating the need for epoxy and utilizing engineered compression seals we remove errors associated with variable epoxy curing and technician discretion, streamlining the sample preparation process. Our extensive range of test cartridges can characterize samples ranging from small, filled blister cavities to large trays. We even have a system designed for multiple K-cups to provide an aggregate “lot” analysis.

For unique package designs, we can create custom test cartridges. For example, bottle barrier testing has historically been performed via sealing the mouth of a bottle to a plate integrated with carrier gas lines (illustrated in ASTM F1307). To minimize sample preparation variances due to the epoxy seal, we have designed custom bottle cartridges tailored to specific thread and flight dimensions. This cartridge was designed to simply screw the bottle into the cartridge itself to create the same leak-free seal as the bottle’s standard cap. The outcome of this cartridge is a cleaner, faster sample preparation with better repeatability. This type of cartridge can be created for any bottle thread geometry.

If you’re seeking simpler sample preparation for transmission rate testing packages, let us know how we can help.

For more information, download these brochures:

Package Test Cartridges: Bottles, Cups and Trays

Package Test Cartridges: Coffee Capsules

Literature

New film and package cartridge brochures (click images below):

Curious for more? Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Upcoming Events

We are excited to announce our attendance at the following trade shows and conferences in the U.S. and worldwide for the remainder of 2025!

Please see the schedule information below to check if we are located near you!

For customers located in the United States, we'll be at:

Pack Expo 2025

- Location: Las Vegas

- Days: Monday, Sept. 29 - Wednesday, Oct. 1, 2025

- Booth Number: N-5808

For customers located in Europe, we'll be at:

ZLV Packaging Symposium 2025

- Location: Allgäu, Germany

- Days: Thursday, September 11, 2025 - Friday, September 12, 2025

- Tabletop Display

Air Quality & Emissions Expo

- Location: Birmingham, England

- Days: Wednesday, September 17, 2025 - Thursday, September 18, 2025

- Booth Number: AQE U72

PPMA Total Show 2025

- Location: Birmingham, UK

- Distributor Name: Tendring Pacific

- Days: Tuesday, September 23 - Thursday, September 25, 2025

- Booth Number: C22

Follow us on LinkedIn or visit the events page on our to be the first to know about upcoming industry events and opportunities to learn more about our solutions.