Accurate Permeation Testing of Complete Packages with Film Analyzers

AMETEK MOCON has introduced a better solution to achieve accurate and repeatable permeation testing of complete packages. Traditional methods of testing packages are messy and time-consuming and yield variable results due to the artsy methods required to prepare the packages and connect to the analyzer.

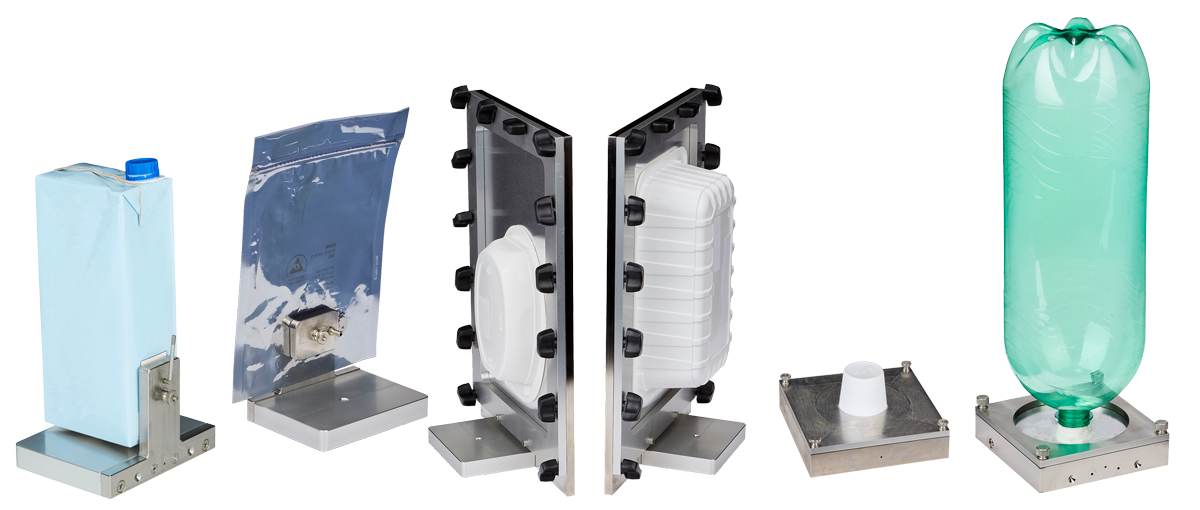

To improve the quality of permeation test results for packages, our engineers created new package mounting fixtures for a range of different package types and a tool-less connection system.

The integrated package testing cartridges are designed in a way to mount the packages without the use of epoxy. This saves a lot of time, mess and reduces variability from sample to sample. While there are a number of these available for different package types, the flexible pouch testing cartridge is especially popular.

The cartridges that utilize disposable foils can be used on a range of package sizes, but they eliminate the need to heat and scrape the old epoxy from the reused plates after every test. They simplify the mounting process and can be done in large batches to save time.

The entire range of package testing cartridges can be connected to an analyzer without tools using our pneumatic mounting system. This system is used on our package testing instruments like the OX-TRAN 2/48 & 2/40 as well as the AQUATRAN 3/40. But MOCON also offers the PackRack fixture that connects to any of our film analyzers, allowing them to test complete packages using our package cartridges.

To learn more about the PackRack and our custom cartridge solutions, please visit our website:

Thicker Bottles, Better Barriers: Enhancing Product Preservation

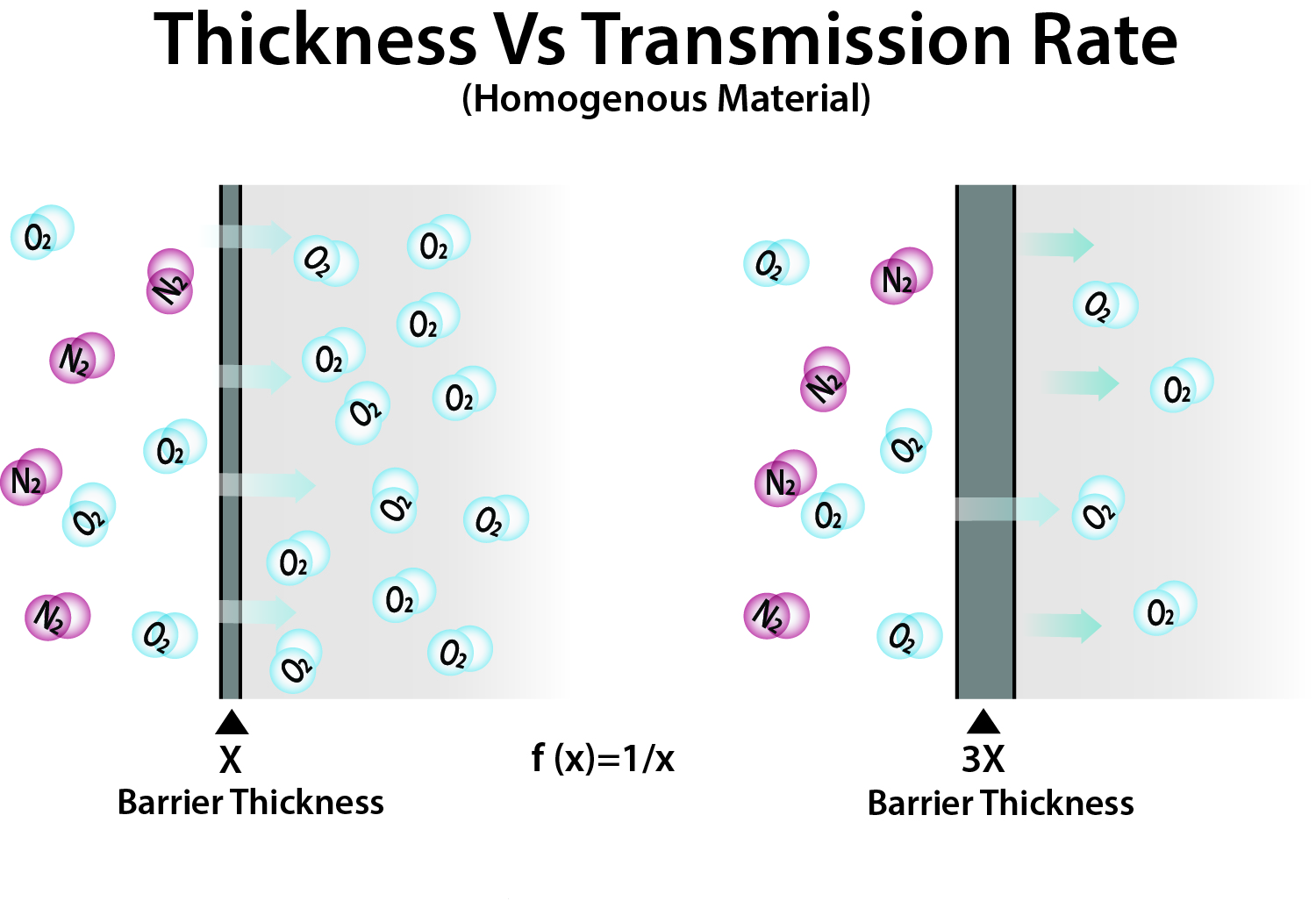

The thickness of a bottle wall plays a critical role in determining its effectiveness as a permeation barrier. Permeation, the process by which molecules pass through a material, can significantly impact the shelf life and quality of the product within. By simply increasing the thickness of the bottle, manufacturers can enhance its barrier properties.

The diffusion rate of molecules through a material is inversely proportional (1) to the thickness of the material. Thicker walls increase the permeation path link, forcing permeant molecules to transverse a longer distance, which slows down the diffusion process. For homogenous materials, there is also a relationship (2) between wall thickness and test time to reach equilibrium; directly impacting QC testing throughput.

Thicker bottles offer superior mechanical strength, making them more resistant to damage and stress during handling and transportation. This reduced risk of physical damage further contributes to maintaining product integrity. Thicker bottles help preserve the freshness, flavor and nutritional value of products like juices, milk and sauces.

Increasing side wall thickness for mono layered bottles in some cases may be a sustainable alternative to applying barrier coatings since the mono-material is easier to recycle, although more material does take more energy to produce. Thus, there’s a fine balance between necessary barrier performance, package requirements and product shelf life.

.jpg?revision=e2e1a016-e109-44a9-816f-3891a96ffde2&h=319&w=269&la=en&hash=1587AD7AA6DDBF6316BD5A9AF49B973B)

Literature

Revised or new brochures (click images below):

.jpg?revision=ac36bd6c-edb8-44f6-97e6-afaaeb91fb5b&h=260&w=200&la=en&hash=8BF7C20503C4F256289FA7D8EA98061A)

Curious for more? Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Events

Coming in

spring 2025 is our 17th Permeation Conference! Hosted by AMETEK MOCON. Next year's conference will take place in the countryside near

Höhr-Grenzhausen, Germany. To learn more about the conference, please visit the link below:

Read More

Want to know where to find AMETEK MOCON in 2025? We're finalizing our trade show schedule now!

Follow us on LinkedIn or visit the events page on our to be the first to know about upcoming industry events and opportunities to learn more about our solutions

Events