Optimizing Oxygen Barrier Testing: Choosing the Right ASTM OTR Method

Oxygen transmission rate (OTR) is a critical metric for understanding how well a material or package blocks oxygen, which can drive spoilage, oxidation and reduced shelf life. But there is no one-size-fits-all method. Selecting the most appropriate ASTM OTR test method can make all the difference in obtaining meaningful results – and ultimately, in designing more robust barrier solutions.

Why OTR Testing Matters

Oxygen is often the enemy of product longevity. In food, pharmaceuticals and medical devices, oxygen ingress can lead to oxidation, off-flavors, microbial growth and degradation of sensitive actives. That’s why knowing how much oxygen a film, sheet or whole package allows in – and under which conditions – is vital. Reliable permeation data helps R&D teams choose materials, engineers optimize packaging and quality control labs maintain consistency and compliance.

Key Considerations for Method Selection

When choosing an OTR test method, there are several important factors to weigh:

- Barrier strength: Is the material a high-barrier film, or more permeable and transmissive?

- Form factor: Are you testing a film, a pouch, or a whole package (such as a bottle with closure)?

- Sensitivity needs: Do you need ultra-low detection of oxygen or are you measuring higher transmission rates?

- Humidity: Will relative humidity affect permeation? (Many materials, like EVOH or coated paper, are moisture-sensitive.)

- Turnaround time: How quickly do you need equilibrium and how long are you willing to run tests?

- Standards compliance: Which ASTM (or equivalent ISO, JIS) standard is relevant to your application?

ASTM OTR Methods — What’s Available

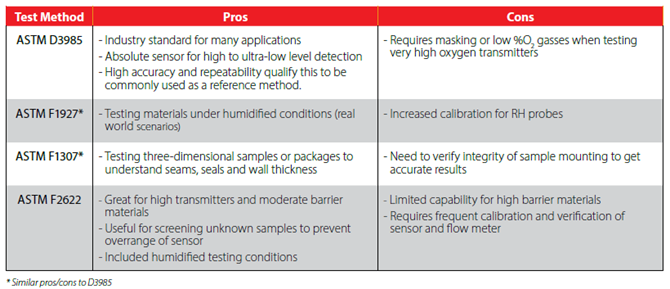

Here are the primary ASTM methods in use and how they compare:

1.

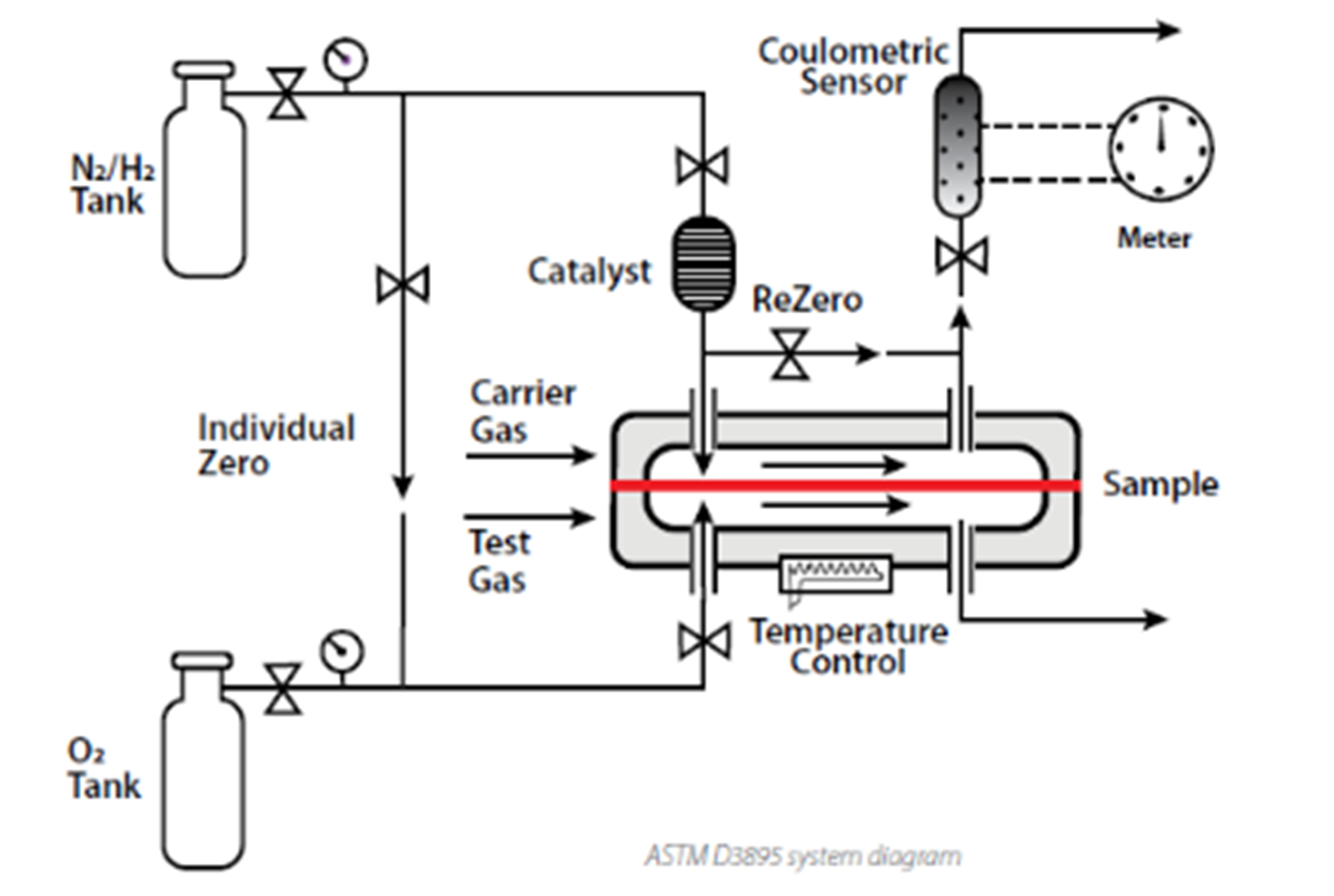

ASTM D3985/F1927 This is the classic “coulometric sensor” method that has been the go-to industry standard since 1981. One side of the film (or package in the F1927 case) is exposed to dry oxygen, and the opposite side is swept with dry nitrogen (ASTM F1927 incorporates humidity to the gases). The transmitted oxygen is carried into a coulometric (electrochemical) sensor, which quantifies the oxygen.

- Strengths: Very sensitive, reliable and widely recognized. An intrinsic standard that does not require calibration.

- Best for: High-barrier films, applications where low OTR detection is critical and tests under controlled humidity

- Tradeoffs: Equilibrium can take hours or even days, especially for materials with very low permeation.

2.

ASTM F2622 This method allows for a wider variety of sensor types (non-absolute coulometric), including generic oxygen sensors. Instead of consuming all oxygen, only a fraction is analyzed, meaning the sensor must be carefully calibrated and continually verified.

- Strengths: Works for higher-transmitting materials, often faster and flexible in sensor choice.

- Best for: Fast-transmitting films (e.g., produce packaging, coated papers), where ultra-low barrier isn’t needed.

- Tradeoffs: Less sensitive than coulometric, and calibration is required to maintain accuracy.

3. ASTM F1307 This method is tailored to whole, finished packages rather than just films. The package is exposed to oxygen on the outside, while nitrogen sweeps the interior. Any oxygen that permeates the package walls is measured using a coulometric sensor.

- Strengths: Measures real-world barrier performance, including closures, seams and other package features.

- Best for: Tray systems, pouches, bottles, tubing/hoses and any packaged format where the integrity of the entire system matters.

- Tradeoffs: Achieving equilibrium in large or complex packages may take considerable time and setup

Putting It All Together: How to Choose

Here’s a framework for selecting the right method:

- Choose ASTM D3985/F1927 when your top priority is maximum sensitivity and you’re testing flat films or sealed systems. Innately works with no calibration needed.

- Use ASTM F2622 when dealing with high-transmission materials, where speed and flexibility matter more than ultra-fine detection.

- Select ASTM F1307 when package-level performance is your concern – if you want to measure how your finished package (seals, closures and all) transmits oxygen.

Moreover, your choice should align with your product’s real-world conditions. For products stored in humid environments, choose a test that accounts for relative humidity to ensure accurate performance results. If your product is refrigerated, stored at room temperature or kept at high heat, make sure to test it at the appropriate temperature to meet your shelf-life requirements.

Expert Support Matters

Implementing these test methods successfully requires more than just choosing a standard. Precision instrumentation, rigorous calibration, and a deep understanding of permeation behavior are essential. Companies often rely on labs or specialists - like AMETEK MOCON – that offer purpose-built OTR analyzers (such as their OX-TRAN series) and testing services to guide method selection, execute tests, and interpret results.

Final Take-Aways

- Understanding which ASTM OTR method to use is foundational for accurate barrier assessment.

- Different materials and package formats require different approaches; there's no universal solution.

- Sensitivity, speed, humidity, and sample configuration should guide your decision.

- Partnering with experienced labs or using specialized permeation tools can help you get reliable, actionable data.

By thoughtfully matching the test method to your specific OTR needs, you can generate more meaningful data, optimize your materials, and build more reliable oxygen barriers – all of which strengthen product performance and brand integrity.

For a longer exposition on which OTR testing method might be right for your application, please download

our latest white paper.