Accurate, Repeatable Results with the Carton Testing Cartridges

For more than 55 years, we have created solutions that make our customers’ lives easier. Whole package testing is a crucial part of the manufacturing process, and we’ve developed a unique cartridge solution that businesses won’t find anywhere else on the market.

Traditionally, companies have to mount packages on tubes with epoxy, which is messy, time-consuming and wasteful. Our carton testing cartridge is a simpler way of running a whole package test without the need for epoxy. A reusable fixture that provides more accurate and repeatable results, this cartridge works with our permeation analyzers designed for package testing or instruments designed for film testing with the addition of the PackRack adaptor.

Understanding Whole Package Testing

Skipping whole package testing can lead to a whole host of issues. Companies need to ensure they have a reliable process in place so their products maintain their integrity from production to distribution. Our carton testing cartridge creates a repeatable process. We developed it in 2020 to address a customer’s need for testing paper cartons, which are difficult to test due to their stress-concentrated leak areas (i.e. seams) and embedded barrier layers. This mostly applies to coated paper products in the food and beverage industry, like a juice carton or compostable packaging.

As companies are putting greater emphasis on creating recyclable and compostable materials, they’re testing more coated paper barriers. When trying new things, AMETEK MOCON’s cartridge makes that process more simple and reproducible so they can move to mass production more quickly knowing their packaging meets industry standards.

Simplifying and Creating Repeatability in the Testing Process

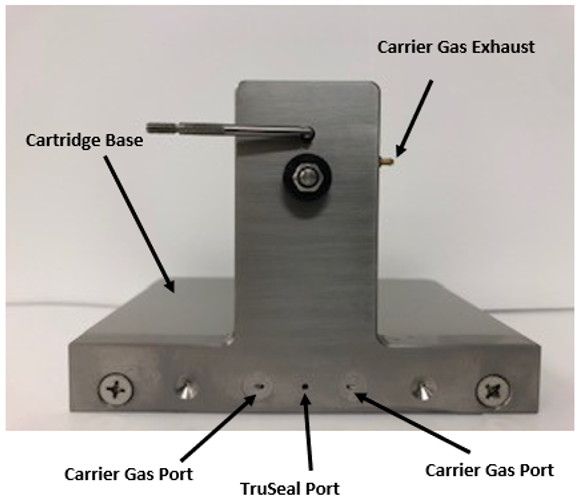

This cartridge is used by cutting a section out of a carton’s sidewall. An insert sits inside the cutout that is pulled through and sealed to the base of the cartridge. The insert allows carrier gas to flow inside the carton and be routed to a detector. Your business can then quantify the amount of oxygen or CO2 that is entering the carton. Our compression-sealed interface, equipped with our patented TruSeal® technology, allows faster and easier prep while providing more reproducible and accurate results.

The Benefits of Our Carton Testing Cartridge

Our cartridge removes the need for copper tubing and epoxy and eliminates leak points. Companies using epoxy could have bad batches that have passed the expiration date. The tube and epoxy process also takes a lot of time. When analyzing cartons at high humidity levels, the epoxy must sit overnight to fully cure. Using epoxy past its use date may also compromise its integrity, thus increasing variability in your values.

Our carton testing cartridge uses our unique and trademarked TruSeal® technology, compatible with our Oxygen and Water Vapor whole package permeation analyzers. With the PackRack accessory, customers with other film testing instruments can also benefit from the ease of use these cartridges provide.

Cutting-Edge Solutions

At AMETEK MOCON, we understand our customers’ needs and partner with them to create package testing products that fit their work. Whole package testing is an essential part of the production process, and the integrity of your products is too important not to have a trustworthy system in place. With our cutting-edge carton testing cartridge, our customers will find a one-of-a-kind product that allows them to test whole packages in less time and with more accurate results.

Watch our VLOG: Carton Testing Cartridge for MOCON Permeation Analyzers

For more information about how this cartridge can work for your business, please get in touch with your sales representative today.