Faster, Easier and More Accurate: The Future of Testing Cups and Capsules

Cups are used in various sectors from coffee capsules to microwaveable soups. Permeation testing of cups from the food and beverage industries comprise a sizeable percentage of total packaging. Traditional permeation testing of these materials consists of using epoxy to glue the sample to a metal plate and purging the inside with nitrogen gas to direct any permeated molecules through the detector.

However, using epoxy can be messy, time-consuming and subjective. A QC testing environment requires optimal test throughput to maximize efficiency. As a result, you need a faster, easier and more repeatable method for prepping these materials.

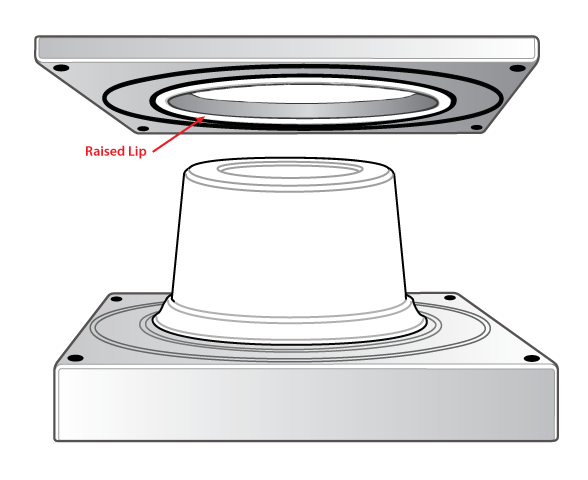

The new custom cup cartridge design allows technicians to secure a test cup by a compressive force for any cup diameter within approximately 3.5” (you can design a test for larger specialized cups as well). Since injection molded cups have flanges, the cartridge top plate with a protruding lip that has the same diameter as the cup compresses the flange area when being secured to the base (figure 2). Multiple-sized cups only need a custom top plate to match the flange diameter while utilizing the same cartridge base (figure 3). This easily facilitates testing of various cup sizes using the same cartridge base (i.e., 80 cm2 cartridge base).

This method is nondestructive and provides more accurate results than using epoxy, since the epoxy covers some of the cup area (producing a slightly lower, false transmission rate).

To learn more about MOCON custom cartridges and their benefits, read the full product brochure below:

Time is Money: Accurate Pharmaceutical Packaging Development with Instrumental Barrier Testing

Pharmaceutical packaging typically uses blister packaging, which normally features high-barrier materials that hold a single dose (such as a tablet). They consist of a thermal-formed cavity that holds the tablet and a flat lid that seals the product in place.

As such, the industry needs to understand the oxygen and water vapor barrier characteristics of these cavities to ensure the efficacy of the drug product. Permeation of gasses occurs in three areas: the molded cavity, the flat lidding, and the seal between the two.

Barrier testing of blister packages can take an exceptionally long time, as both the oxygen and water transmission rates are low, and it is a challenge to quantify using traditional techniques. For WVTR, this has historically been measured through gravimetric (weight gain) studies. For OTR, companies measure the chemical degradation of the product relating to oxidation. As these tests often have exceedingly long test durations - weeks or months, even in accelerated environments - it is often easier and faster to measure OTR and WVTR with high-sensitivity instrumental methods.

With these instrumental results, a pharmaceutical company can screen and select material candidates and suppliers more efficiently. For a smaller group of packaging candidates, this translates to time and cost savings when conducting necessary stability studies.

Testing includes:

- Films for Lidding – These are readily analyzed with standard film transmission rate testing.

- Formed Blister – These can be analyzed independently (such as verifying mold cavity design) via sealing the cavity to a foil film that has a hole and measuring the transmission rate through the mounted sample

- Blister “System” – Measures the transmission rate through the cavity, film and includes the seal. For many systems, the seal is a critical component. This Blister “System” is best analyzed for WVTR if liquid is secured inside the cavity with factory seals. If this cannot be done, you can inject water into the cavity and seal the injection site with epoxy. One key item with sealed blister systems is that if the overall transmission rate is low, adding multiple filled blisters to the test cell will generate more water vapor signal and allow for better low-level testing.

Resources

Revised or new application notes (click images below).

.jpg?revision=84358b0c-e26a-499f-8686-b56c71b711ba&h=334&w=250&la=en&hash=38E9C589B0E5FB3167061E1242489FB1)

.jpg?revision=7e9643bb-bb5d-40dc-8465-06931696aec7&h=334&w=250&la=en&hash=97B954CE4FF4574F600729C047D39D2B)

Curious for more? Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Events

We are halfway through our 2024 trade show season. We are excited to announce our second half of trade shows and conferences worldwide! Please see the schedule below to see if we are coming to a location near you:

Coming in spring 2025 is our 17th Permeation Conference! Hosted by AMETEK MOCON. Next year's conference will take place in the countryside near

Höhr-Grenzhausen, Germany.

To learn more about the conference, please visit the link below:

Read More

For

customers located in the United States, we'll be at:

Pack Expo International 2024

- Location: Chicago, IL

- Days: Sunday, Nov. 3 - Wednesday, Nov. 6, 2024

- Booth Number: W-17080

For

customers located in Europe, we'll be at:

Multilayer Packaging Conference

- Location: Vienna, Austria

- Days: Tuesday, Dec. 10 - Wednesday, Dec. 11, 2024

- Booth Number: (TBD)

Currently, we have no shows scheduled in Asia for the rest of 2024.

Our list of 2024 trade shows and events is now final. Check the link below to our events page to see where we will be!

Events