Leak Testing in Gas Transmission Rate Analysis

Testing full packages – including seals and closures – for gas transmission rate is essential to assess barrier performance and ensure product stability. These tests measure how much oxygen, water vapor or carbon dioxide permeates through packaging materials.

A critical but often overlooked step is screening for leaks. Defects, poor coatings or weak seals can allow gases to bypass the material, skewing transmission rate results and misrepresenting the package’s true barrier properties.

Simple visual methods like the Bubble Emission Test (LeakPointer

® H

2O) help detect leaks by submerging pressurized packages in water. For films, applying slight pressure beneath the material with water on top can reveal flaws. Other tests, such as Gurley porosity (for coated paper) and Pressure Decay (for pouches), are useful but don’t visually pinpoint leak locations.

Leak testing ensures gas transmission occurs only through the intended material, preserving the accuracy of results and supporting the development of reliable packaging solutions.

Smarter Packaging Starts with Strategic Permeation Testing

Using data-driven permeation testing in packaging design is crucial to balancing cost, performance and sustainability. Many packaging projects fail due to under-packaging (leading to spoilage and brand damage) or over-packaging (causing unnecessary cost and environmental burden).

To optimize shelf life, development teams should do the following:

- Define product tolerance to oxygen or water vapor (per product needs)

- Verify barrier material permeation data

- Model package performance to determine proper levels

- Validate prototype packages under real-world conditions

Integrity testing, distribution simulations and iterative adjustments are also critical. Rapid permeation testing provides faster feedback than traditional storage studies, enabling more agile development cycles.

The most common pitfalls in packaging permeation testing include mismatched lab and package data, excessive conservatism, production equipment and process variability, and ignoring seal integrity. To avoid these issues, teams should validate early and independently, and use permeation data proactively to guide smarter, more efficient design.

Ultimately, using permeation testing as a strategic tool can empower teams to design smarter, more sustainable packaging that meets shelf-life goals without over-engineering.

At Pack Expo 2025, our experts will be on hand in booth N-5808 to answer your most pressing permeation testing questions to help you improve your packaging for longer shelf life.

For more information on smarter packaging, read lab manager Joel Fischer's article "Smarter Packaging for Longer Shelf Life" in the new issue of Packaging Technology Today:

Read More

Egress Testing in Healthcare Applications

Capture Volumes (Healthcare)

Permeation testing may be executed in different ways to acquire the barrier properties of a packaging system. For example, within the healthcare sector, many products contain liquid or some type of solution. To evaluate the moisture barrier characteristics of these packaging systems, egress testing is easier and more of a ‘real life’ scenario since the package has gone through the supplier’s manufacturing process.

Many whole package permeation tests remove the contents of a package prior to evaluation. Measuring oxygen or moisture ingress from the outside environment. Egress testing syringe delivery systems, saline bags, blister packs, and other liquid application pharmaceuticals, uses the product itself to provide the moisture driving force for the most applicable permeation test.

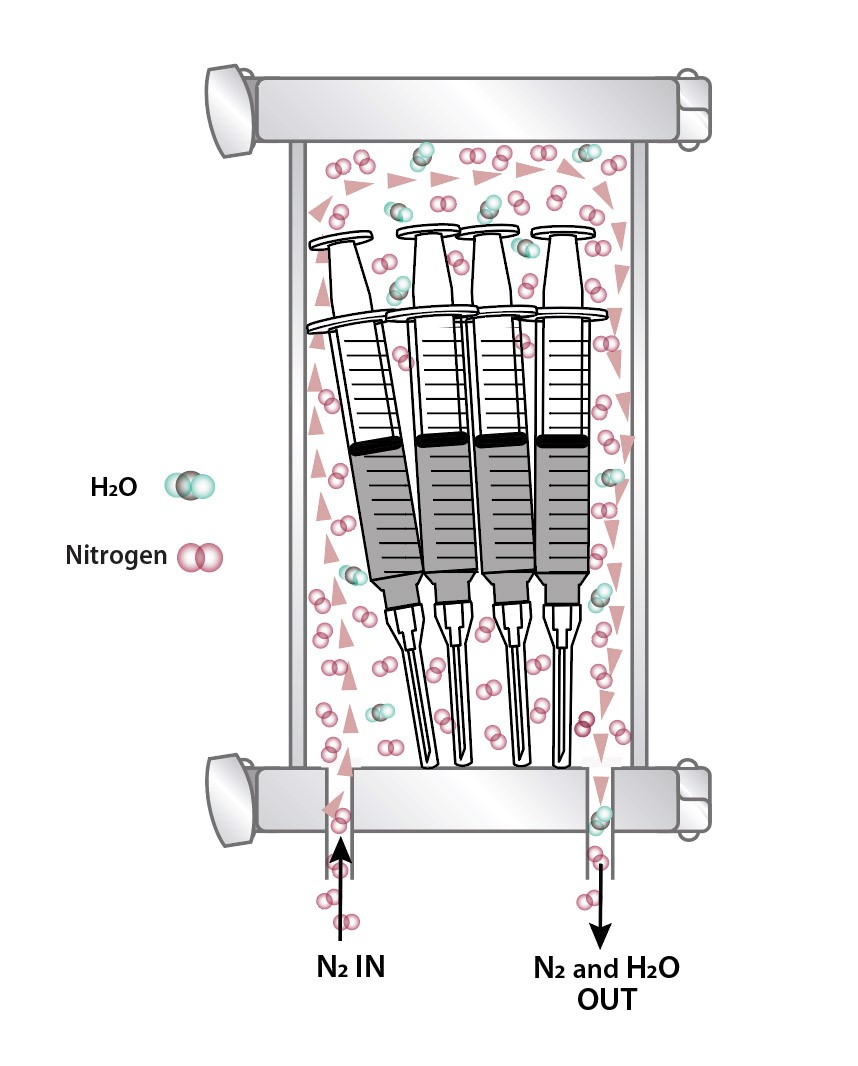

Egress permeation testing consists of sealing the package within an impermeable vessel that purges the inner volume with nitrogen gas to route any permeated moisture to a detector (fig 1). Historically this was done by sealing the sample (using epoxy) within a glass jar onto a brass plate having purges lines. Metal vessels that have reproducible hermetic sealing capability decreased overall testing time while increasing repeatability. This is due to the potential curing variability of the epoxy, and metal having a much lower affinity for moisture versus glass speeding up the outgassing process.

Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Upcoming Events

PMMI Webinar: Tuesday, October 21st!

So nice, we’re doing it twice! AMETEK MOCON and PMMI are partnering for another webinar on package testing in 2025. This time, it will happen on Tuesday, Oct. 21 from 1:00-2:00 p.m. EST.

During “The Right Stuff (Materials) to Develop Your Perfect Package,” our Lab Manager, Joel will explain how to align materials with manufacturing needs, product performance and sustainability goals. Whether you package food, pharmaceuticals or electronics, this presentation will help you:

- Evaluate materials under real-world conditions

- Improve shelf life and product integrity

- Benchmark against competitors using industry standards

To attend this free webinar, click below:

Register Now

We are excited to announce our attendance at the following trade shows and conferences in the U.S. and worldwide for the remainder of 2025!

Please see the schedule information below to check if we are located near you!

For customers located in the United States, we'll be at:

Pack Expo 2025

- Location: Las Vegas

- Days: Monday, Sept. 29 - Wednesday, Oct. 1, 2025

- Booth Number: N-5808

For customers located in Europe, we'll be at:

OE-A Meeting Europe

- Location: Warsaw

- Days: Tuesday, Sept. 30 - Wednesday, Oct. 1, 2025

- Our lab services manager Joel Fischer will be giving a presentation on "Testing and Qualifying Flexible Ultra-barriers - Supporting the Round Robin Test."

Follow us on LinkedIn or visit the events page on our to be the first to know about upcoming industry events and opportunities to learn more about our solutions.