How We Achieved a World-Class Status and What It Takes to Maintain It

1966 was a remarkable year in America. The Chicago Bulls and New Orleans Saints were expansion franchises of the NBA and NFL, respectively; Star Trek debuted, captivating audiences with visions of future technological wonders; and a small company in Brooklyn Park, Minn., began operations with some groundbreaking technology of its own.

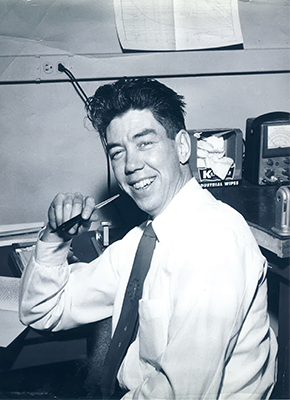

Manual barrier testing is time-consuming, difficult, and often lacks repeatability. Our founder, Les Demorest, sought to address the primitive nature of existing permeation testing techniques by providing automated, highly repeatable testing of packaging materials. His invention (the Infrared Detector or IRD) was the first instrument to measure water vapor permeation through coated papers.

This new method was not only significantly faster than existing testing methods, but also more accurate. Over the next half-century, AMETEK MOCON continued to innovate, becoming the world leader in permeation testing with automated, accurate testing equipment and the largest permeation testing laboratory in the world. How did we do it?

Industry Leadership

Our combination of world-class instrumentation and a world-class laboratory sets AMETEK MOCON apart as a leader in permeation testing. We are proud of our team members' active participation in worldwide standards organizations (such as ASTM, where AMETEK MOCON Lab Manager Joel Fischer serves as Chair of the F02.10 Primary Packaging Permeation Subcommittee).

Permeation rate measures the number of grams of a substance per square meter that passes through a barrier in a given period. Instead of calling it the permeation rate, our customers often call it the "MOCON number.” When your company's name becomes a de facto unit of measurement, you have made a strong and lasting impact on the permeation field.

Sensitivity and Accuracy

When measuring high-barrier materials, the gas levels detected are in the parts per billion (ppb) range. Accurately measuring is extremely challenging and requires high-quality engineering to create leak-free instruments and custom-made sensors with low-level sensitivity. We are committed to providing our customers with the precise and reliable measurements they need.

Because sensitivity without accuracy would lead to unreliable results, our high-barrier instruments utilize intrinsic detectors (coulometric for O2) that ensure accuracy without the need for calibration.

Versatile Cartridges

Manual permeation testing often requires each test to be set up individually. The material to be tested must be manually attached to the test instrument, and variations in this setup process can cause variations in the results. AMETEK MOCON's unique solution to this problem is the crown jewel of our instruments.

In 1966, MOCON pioneered the sample mounting process by introducing cartridges in our PERMATRAN-W® 700 instruments. Today, we have expanded on the cartridge design, developing additional cartridges for a variety of applications.

By using our instruments' interchangeable cassettes, customers gain several immediate benefits. They can test packaging materials repeatedly without worrying about assembly inconsistencies, and they can test for different properties, such as the transmission rate of oxygen, carbon dioxide, and water vapor, using the same cartridge. This improves accuracy and increases convenience and test throughput.

We continue to innovate our cartridges. As customers develop new materials to test, we create a cartridge to meet their needs. When the Keurig® coffeemaker was invented, K-cups needed to be tested to ensure that the coffee inside wouldn't go stale. We developed a K-cup cartridge specifically designed for the shape and materials of these unique packages.

AMETEK MOCON's cartridges future-proof our machines, giving us the flexibility to perform tests that aren't needed today but will be in the future. That is why our instruments and accessories have been the gold standard for more than half a century. But instruments are only part of the picture; our permeation lab also plays a critical role in keeping us on top.

World’s Largest Permeation Lab

The AMETEK MOCON permeation lab, the largest in the world, staffs the foremost experts in permeation analysis of a wide range of materials. Our lab is ISO 17025-accredited by the American Association for Laboratory Accreditation (A2LA), ensuring our equipment and procedures produce reliable, accurate, and repeatable results.

After measuring thousands of different types of films and package configurations, our applications specialists and lab technicians have the expertise ranging from routine testing to developing new methods for testing cutting-edge materials. Whether customers need backup testing to confirm their results or want to turn all their testing over to us, our lab is always ready to meet their needs.

Maintaining world-class status isn’t easy. It takes a significant investment of capital, training, and resources for AMETEK MOCON to produce top-tier instruments and operate the best permeation lab in the world. But we know it’s worth it. Our relationship with our customers is a long-term partnership, and we embrace innovation and excellence because that’s what those valued partners deserve.