Packaging is a pivotal part of supply chains, ensuring products reach consumers safely and intact. Yet, leaking or damaged packages pose significant risks, including product spoilage and wasted resources. With growing environmental impact awareness and consumer preference driving the shift toward sustainable materials, maintaining package integrity and shelf life has become more important – and more challenging – than ever before.

Limitations of Traditional Packaging

Plastic has been the material of choice for packaging liquids, food products and sterile medical devices for decades. Its exceptional leak resistance, versatility in molding and sterility maintenance made it indispensable. Perhaps most importantly, it was also cost-effective, leading to widespread adoption.

However, the environmental consequences of plastic are a growing concern. While advancements have led to bio-based plastics derived from renewable resources like sugarcane or corn, the production and disposal of traditional petroleum-based plastics continue to harm the environment. Indeed, only a small fraction of plastic waste actually gets recycled, and its decomposition can take centuries.

Transition to Sustainable Packaging

In response, companies are increasingly exploring sustainable alternatives such as paper-based packaging.

While paper offers promise due to its biodegradability, it also presents unique challenges. Paper’s porous nature makes it prone to gas and liquid leakage, rendering it unsuitable for certain applications like beverages, solid foods and sterile medical devices. High-barrier coatings – ultra-thin layers of protective materials – help overcome these limitations, enhancing recyclability while maintaining necessary performance characteristics.

Innovative solutions, such as high-barrier films with less than a certain percentage of plastic, represent a key area of focus. These alternatives attempt to balance functionality with environmental responsibility, enabling companies to transition to sustainable packaging without compromising quality or usability.

Advancements in Barrier Film Technologies

The development of ultra-thin barrier membranes has revolutionized paper packaging. These coatings can be customized based on specific product requirements, addressing the need to reduce material waste and conserve energy.

The average consumer may be unaware of their existence, but examples of advanced barrier film technologies are ubiquitous and include:

- Metallic films in potato chip bags

- Polymer films for beverage containers

- Composite materials (such as clay-infused matrices in paper fibers) that offer enhanced barrier properties without relying on traditional coatings

Promising as these advancements may be, companies often lack the necessary testing data to trust their performance characteristics.

The Importance of Barrier Film Testing

Transitioning to sustainable packaging requires rigorous testing to ensure performance and reliability. While reams of data exist from years of testing traditional plastic packaging, there is insufficient evidence about the performance characteristics of these cutting-edge packaging materials.

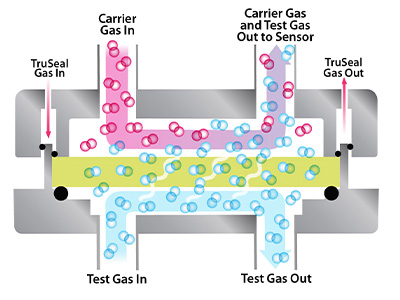

That’s why permeation analysis is such an important part of the supply chain. It’s an essential tool for evaluating how well eco-friendly packaging materials resist the passage of gases, moisture and other elements.

AMETEK MOCON has been a trusted name in permeation testing since 1966, offering a comprehensive range of instruments and services. With expertise in analyzing both traditional and innovative materials, MOCON enables companies to:

- Validate the effectiveness of new barrier technologies

- Profile packaging materials to ensure long-term shelf life

- Generate reliable data through comprehensive testing methodologies

By providing detailed insights, MOCON helps researchers refine their designs, ensuring optimal performance and sustainability.

Innovative Testing Solutions

MOCON permeation testing equipment stands out for its precision and innovation. With a legacy of reliable measurement, the company offers state-of-the-art solutions, including:

- Innovative cartridges for custom testing, addressing unique material challenges.

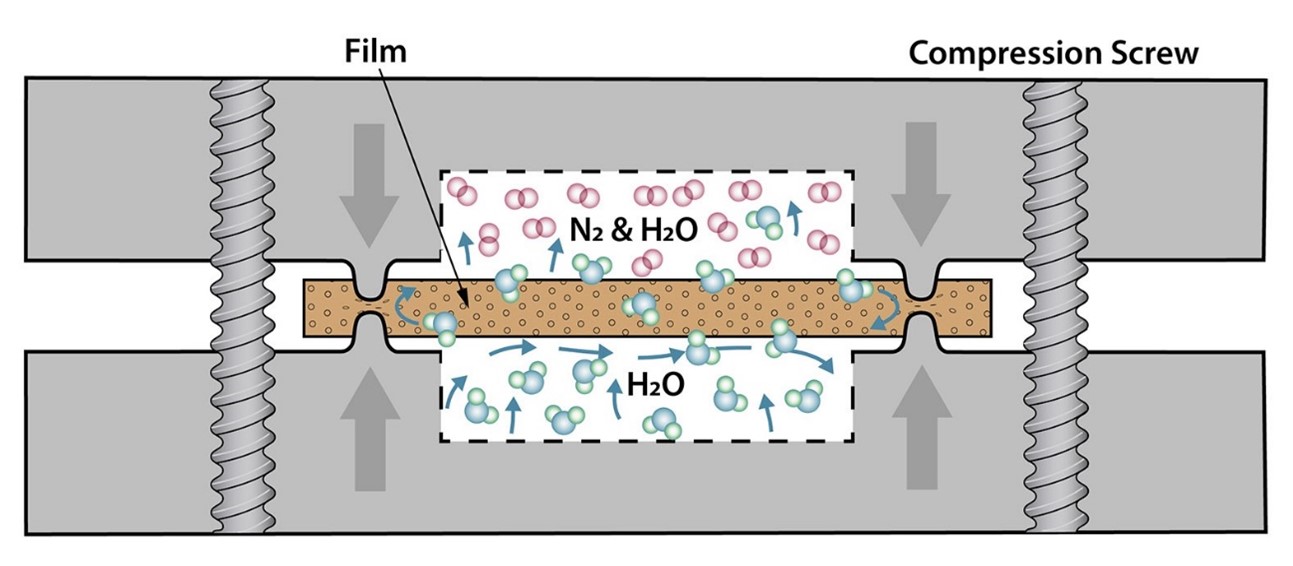

- Edge compression film test cartridges, designed for testing coated paper samples with rough or uneven surfaces.

- Edge effect cartridges, enhancing accuracy for both water vapor and oxygen testing.

These tools are essential for evaluating next-generation packaging materials, ensuring they meet both functional and environmental requirements.

Support Beyond Equipment

In addition to its advanced instruments, MOCON offers services through its world-class testing lab, staffed by seasoned scientists who provide:

- Customizable testing solutions tailored to specific needs

- Comprehensive consultation to help companies navigate complex challenges

- Reliable results trusted by businesses of all sizes

The Future of Sustainable Packaging

As the demand for eco-friendly packaging grows, continuous innovation in barrier film testing will be critical. Present and future developments are prioritizing:

- Increasing recyclability without compromising performance

- Developing new materials and coatings to reduce environmental impact

- Enhancing testing methodologies to address emerging challenges and ensure packaging consistency

Conclusion

Navigating the complexities of sustainable packaging requires expertise, innovation and a commitment to quality. AMETEK MOCON offers all three, serving as a trusted partner for more than half a century for companies who want to reduce their environmental impact without compromising their packaging quality and integrity.