Innovative Solutions for Testing Barrier Materials

As governments push for more environmentally friendly, sustainable packaging across different industry sectors, manufacturing companies are constantly innovating new compostable and recyclable packaging materials. When it comes to R&D of novel materials, businesses like packaging converters and material manufacturers may find that they need additional support – especially for barrier testing. To help our customers in this process, AMETEK MOCON has developed a wide range of unique, application-specific and customer-driven permeation testing accessories.

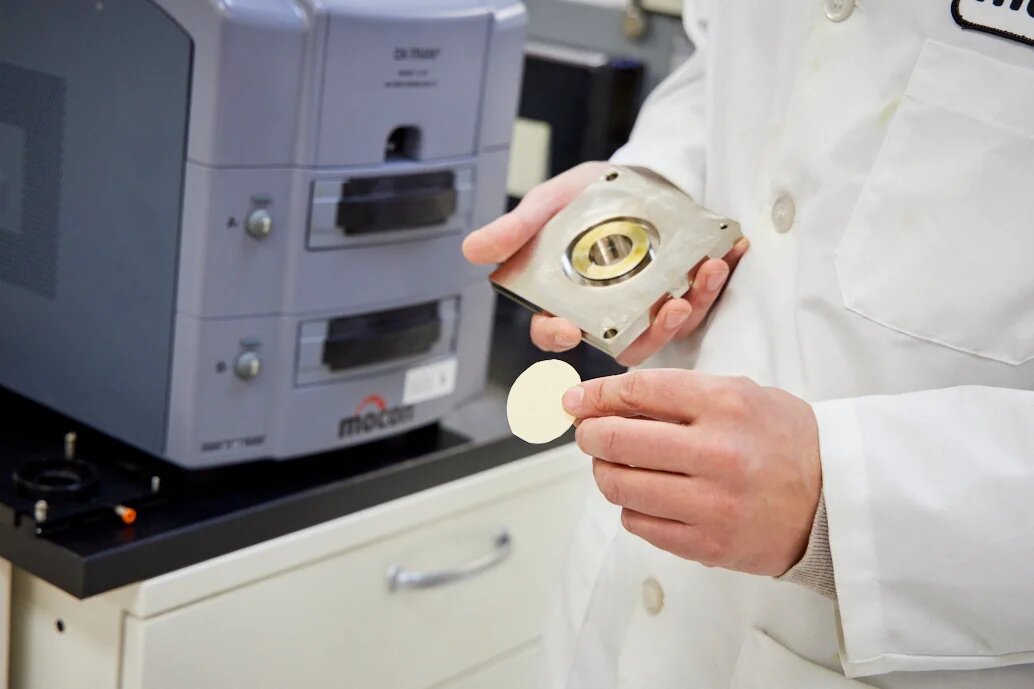

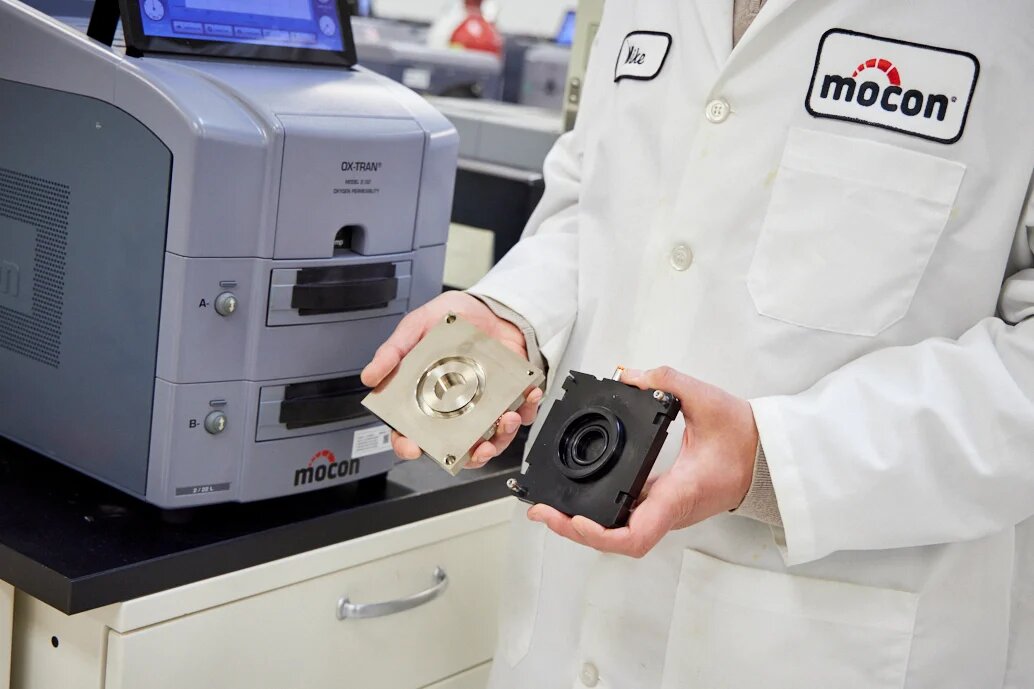

Our family of interchangeable, reusable accessory cartridges expands the capabilities of our industry-leading film and whole-package permeation testing instruments. These cartridges simplify the testing process and increase repeatability, which our customers appreciate for unique and difficult-to-test materials. Some cartridges are dedicated to specific formed packages, while others were developed to test different kinds of film samples – such as the Reduced Area Test Cartridge.

Expanded Test Range with Reduced Area Cartridges

When labs test new materials, they may only have a limited amount of the sample prototype developed. Often, each individual barrier property test permanently damages the sample, meaning it can’t be used for further tests. With our reduced area cartridges, only a small material sample is needed, and it can be reused for further testing. This helps labs collect a broader range of data, which means that when the material moves on to the whole-package stage, you’ll have the peace of mind of knowing it’s the best possible barrier.

Another variable when testing new barrier materials: the transmission rate is unknown and may exceed the normal range of an instrument. Testing with a reduced testing area means less gas will pass through, and it won’t go beyond the instrument’s detection limit or require a special calibration. A range of cartridge sizes also allows for testing with the best signal level for each barrier. By extending the instrument’s upper detection limit and reducing the amount of material needed, these cartridges help streamline the testing process.

Reducing Labor, Time and Cost for Our Customers

Traditional testing methods often require mounting a sample on a single-use mask and securing it with epoxy. This process requires extra materials, more manual labor and increases the variability of results. Our cartridges are simple to use, and setup takes just seconds: Apply a thin layer of grease to the cartridge, mount the material sample and pop the cartridge into your instrument.

We provide the high standard of service our customers expect and require. AMETEK MOCON instruments are the most sensitive on the market, measuring every molecule that passes through a test barrier. With the reduced area cartridge, customers have the benefit of an extended detection limit combined with reliable, repeatable test results. Businesses can trust they’re getting a solution that will save them time and money in the long run

.

Supporting Industry Innovation

AMETEK MOCON is unique in offering a range of application-specific permeation instrument accessories. We develop and constantly improve cartridges based on customer feedback, helping to enhance the use of your machine and of your testing capabilities. On top of that, they’re easy to use. No one else in the industry can offer these solutions, and it’s just one more way we’re revolutionizing the material and package development process for our customers.

Our unique expertise positions us at the forefront of innovating cartridges so other businesses can be at the forefront of innovating new packaging materials. We are your partner in this process. Our focus on customer needs allows us to create user-friendly solutions that revolutionize the testing process with real businesses in mind. To learn more about our cartridges and find one that fits your needs, please get in touch with a sales representative today.