No More Messy Epoxy: Finding a Cleaner Permeation Testing Solution for Packages

Historically, permeation package testing required laborious sample preparation. This messy and time-consuming process involving two-part epoxy, heat guns and exhaust hoods drove most laboratories to avoid or minimize testing of packages. In the AMETEK MOCON testing laboratory, we are well-acquainted with the meticulous preparation methods required for various package types, including pouches, bottles, cups and cartons.

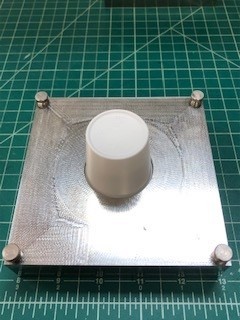

Several years ago, the team at AMETEK MOCON decided there must be a better method to accurately test packages without all the labor and mess. Consequently, we invented a series of test cartridges for a variety of common package types that allowed simplified mounting and improved test results. Customers utilizing these cartridges report increased testing, less labor and more repeatable results.

These cartridges, however, work primarily for common package types and sizes. To assist customers with unique packages, we also offer custom-designed test cartridges. Examples of such cartridges include threaded bottles, fruit cups and coffee capsules. These cartridges allow technicians to mount and test samples with minimal effort and produce more consistent resultswithout the variability of the old manual methods. Plus, there is no messy clean-up to reuse the test fixture (cartridge).

If you want to improve your package testing results and reduce labor, contact your local AMETEK MOCON sales representative to learn how we can help.

To learn more about our custom cartridge solutions, please visit our website:

Don’t Let Moisture Mislead Your Permeation Testing

Permeation testing of moisture-sensitive structures can be misleading due to the varying levels of moisture sensitivity. The barrier properties of a material can change depending on the type of permeant and the level of humidity. A structure that effectively blocks oxygen may not necessarily be a good barrier against water vapor. This is why many packaging films are multi-layered, with each layer providing a specific barrier role for different chemical species.

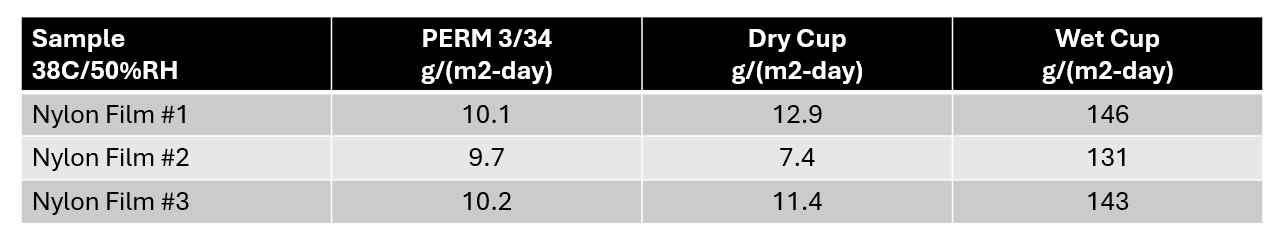

Nylon is a well-known material that is sensitive to moisture. When comparing the oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) for nylon films, it’s important to pay close attention to the test method used. For instance, WVTR results for a typical nylon film can vary significantly depending on whether the test follows ASTM E96 or ASTM F1249 standards. Even when both tests use the same driving force gradient (e.g., 50% relative humidity), the level of transmission may differ based on whether a dry or wet cup method is employed (see Table 1).

The key to obtaining reliable and accurate permeation results lies in tightly controlling both temperature and humidity. This requires the use of precise RH probes and continuous temperature monitoring throughout the test.

According to the Arrhenius equation, temperature is the most critical factor in permeation. Accurate relative humidity is directly linked to precise temperature control, and vice versa. Once you understand the moisture characteristics of your sample, it is essential to carefully select a test method that accurately characterizes your sample’s barrier properties for real-world applications.

Literature

Revised or new brochures (click images below):

Curious for more? Uncover a wealth of knowledge on similar topics and industries in our Resource Library linked below:

Events

As "trade show season" in 2025 begins, we are excited to announce our attendance at multiple trade shows and conferences worldwide! Please see the schedule information below to check if we are located near you!

For customers located in the United States, we'll be at:

Cheese Expo 2025

- Location: Madison, WI

- Days: Tuesday, April 15 - Thursday April 17, 2025

- Booth Number: 1005

Analyzer Tech Conference 2025

- Location: Galveston Island, TX

- Days: Monday, April 28 - Friday, May 2, 2025

- Booth Number: 306

TAPPICon 2025

- Location: Minneapolis, MN

- Days: Sunday, May 4 - Wednesday, May 7, 2025

- Booth Number: 541

AIHA Connect 2025

- Location: Kansas City, MO

- Days: Monday, May 19 - Wednesday, May 21, 2025

- Booth Number: 414

Membrane Technology Forum

- Location: Bloomington, MN

- Days: Monday, June 2 - Wednesday, June 4, 2025

- Booth Number: 5

Global Pouch Forum

- Location: Clearwater, FL

- Days: Wednesday, June 20 - Friday, June 22, 2025

- Booth Number: TBD

Sensors Converge

- Location: Santa Clara, CA

- Days: Tuesday, June 24 - Thursday, June 26, 2025

- Booth Number: 1134

Pack Expo 2025

- Location: Las Vegas

- Days: Monday, Sept. 29 - Wednesday, Oct. 1, 2025

- Booth Number: N-5808

For customers located in Europe, we'll be at:

IFFA 2025

- Location: Frankfurt, Germany

- Days: Saturday, May 3 - Thursday May 8, 2025

- Booth Number: B79

IPACK-IMA and Pharmintech 2025

- Location: Milan, Italy

- Days: Tuesday, May 27 - Friday, May 30, 2025

- Booth Number: B64

PPMA Total Show 2025

- Location: Birmingham, UK

- Distributor Name: Tendring Pacific

- Days: Tuesday, September 23 - Thursday, September 25, 2025

- Booth Number: C22

At this time, we're still finalizing our list for trade shows located in Asia. Stay tuned for an updated list.

Want to know where to find AMETEK MOCON in 2025? Our trade show schedule is now live for the United States and Europe!

Follow us on LinkedIn or visit the events page on our to be the first to know about upcoming industry events and opportunities to learn more about our solutions.